Simon Eccles explains how the use of large format inkjet printing for signage contributes to a significant amount of plastic waste, primarily from self-adhesive flexible plastics like PVC, PE, and PU. Additionally, soft signage printed on woven textiles, often polyester mixes, adds to the environmental impact.

Nearly all of these plastics depend on fossil fuels, which are non-renewable, non-sustainable resources. Sooner or later they will end up as CO2 in the atmosphere – if it happens quickly, by burning, it contributes to climate change sooner, but if it happens slowly (or a period of centuries in landfills), the plastic can break down in various ways that get into the biosphere with various results, none of them good.

Unfortunately these plastics are really, really useful in the large format printing sector, which over the past 40 years or so has come to depend on them almost completely. For flexible self-adhesive applications there’s no easy or practical alternative, but there are some for textiles and rigid boards.

Biodegradable and compostable plastics aren’t the solution they initially seemed to be. Materials designed to break down in the environment obviously don’t last very long, and the total environmental impact of a short-lived sign or display material that has to be replaced frequently is probably much more than a long-lived if unfriendly plastic. Although if the sign is only intended for short-term use and then discarded, the lifetime is less of a problem. However, it’s become apparent that biodegradable plastics simply turn into the unwanted microparticle plastics sooner.

The widely used if somewhat vilified PVC has a long life and is recyclable, though not as easily as some alternatives. There are questions about the safety of its plasticiser chemicals, both during manufacture and as post-use waste. Alternative plastics, such as PE, PET, PU, are also recyclable, but have their own issues.

Really, the main problem with recyclable plastics lies in recovering it to recycle it after use. You can collect all the plastics waste in a printing factory and send it off for certified disposal and probably recycling.

But the main sellable products, the printed signs, banners, decals, vehicle wraps etc, go off into the wide world and are then largely out of control of the original producer. The end user may dispose of them in a safe and sustainable way, but how do you know for sure?

But don’t despair. By adopting sustainable practices, minimising waste, adopting low-energy curing methods, and embracing the circular economy concept where available, the printed signage sector can address the challenge of reducing plastic usage and waste. This article looks at various strategies to minimise waste, recover materials, and promote responsible practices, despite the limited control over end-of-life processes.

Cool running LEDs

While you may not be able to completely stop using plastic, you might be able to use less of it. The introduction of LEDs in UV curing in the past couple of decades has opened up this possibility. LEDs run very cool compared to the older mercury arc lamps for UV curing, which means that you can use significantly thinner plastic media without the risk of heat distortion. Consequently you can use less plastics per square metre of print, which costs less to buy of course, but also cuts down on transport costs (it weighs less and means you can fit more rolls into delivery trucks). There’s less energy as well as plastic used in manufacture too. At the printing stage the LEDs use far less energy and last much longer than mercury lamps.

Not only is LED a good alternative to mercury lamps, but it is also an energy saver compared to solvent and eco-solvent inks, which require heated beds, and HP’s Latex inks, which still need heat even though the company has worked to reduce this in recent iterations of its printers. Dye sublimation is water-based, which is good, but again heat is needed to activate the sublimation transfer stage.

UV-LED inks are available for different flexibility/durability trade-offs, though they’re still not suitable for all applications so solvents and dye sub are often still the only practical solutions.

Rethinking materials and substrates

One step in reducing plastic usage and waste is re-evaluating the materials and substrates used.

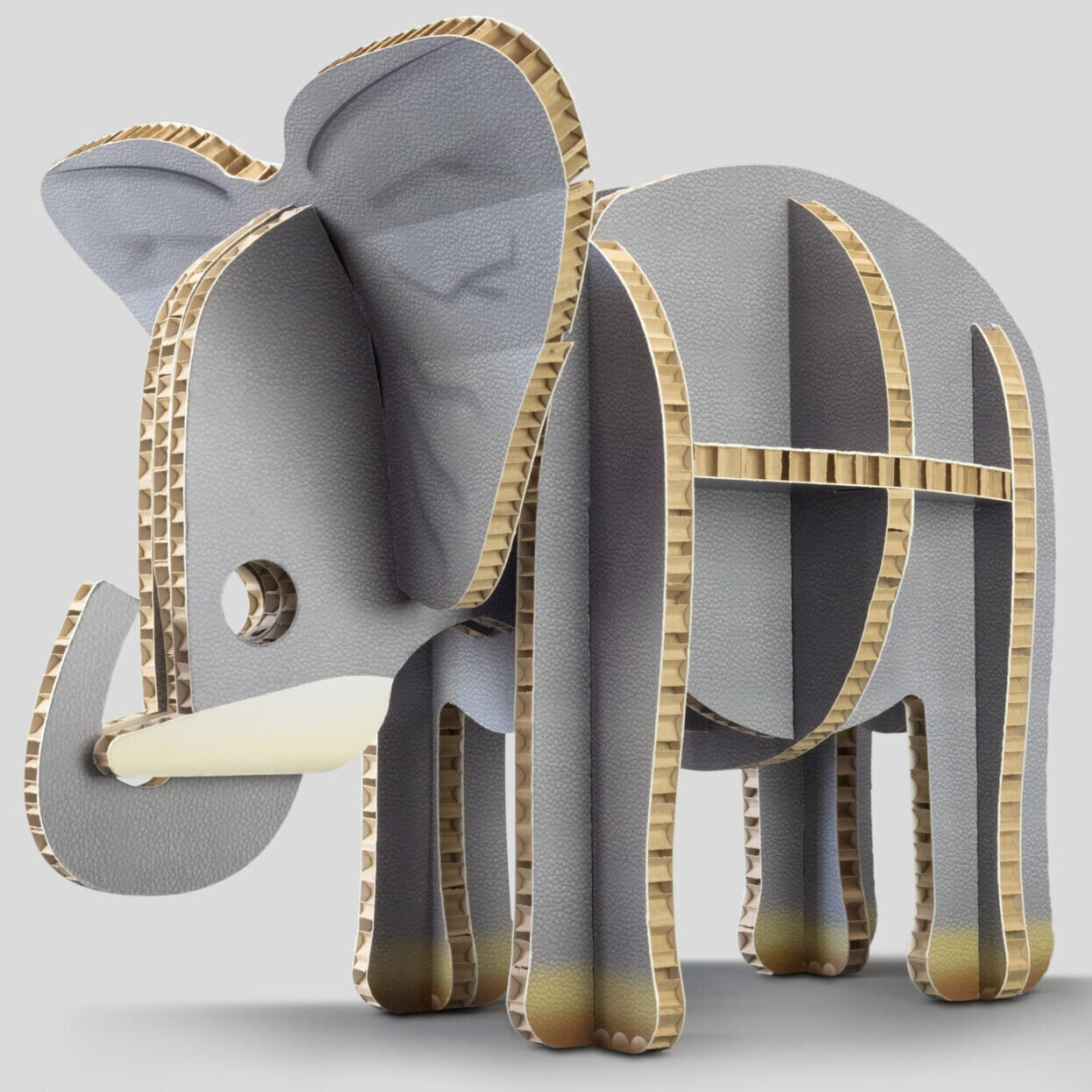

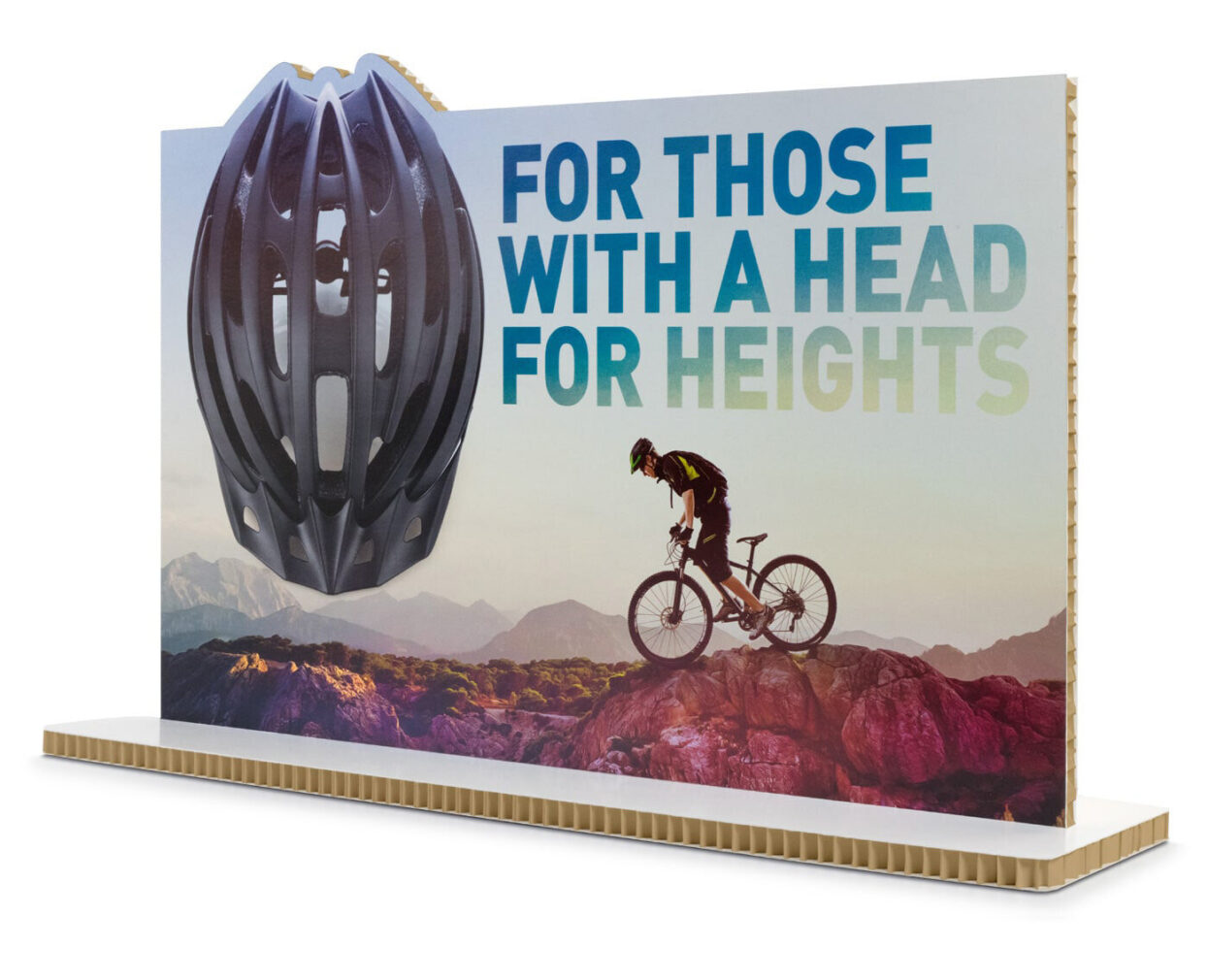

For example, plastic foam boards and even some aluminium composite panels (with plastic cores) for interior use may be suitable for replacement with paper-corrugated sandwich board, of which the best known is the UK’s Dufaylight. This is strong, lightweight, printable and recyclable. It’s also made from up to 85% recycled paper to start with.

While plastics of some form may be the only practical material for self-adhesive media, some have more environmental impact than others. Polypropylene (PP) and polyethylene (PE) are more easily recyclable alternatives for PVC.

Conversely, for long-life applications, the most durable media and inks reduce the need to replace signage that has been degraded by outdoor exposure. It’s a matter of judgement.

PET (Polyethylene Terephthalate) is considered safer and friendlier to the environment than PVCs. This is one of the most commonly used plastics in the world. It’s regularly used to create plastic bottles, food containers, plastic bags, and clothing.

In signage and graphics, clear PET window films have much the same benefits as PVC and are UV-printable. At the end of life, PVC films can break into small pieces, making removal time longer. PET tends to come off in a single sheet for faster removal and easier handling for disposal.

For soft signage, the use of woven textiles made from natural fibres, like organic cotton or hemp, reduces reliance on the polyester mixes needed for the dye sublimation/diffusion process. On the other hand natural fibres require different classes of inks, with environmental and durability issues of their own.

The dye sublimation process will work reliably on up to 80% PE with cotton or other natural fibres, which makes for more comfortable wearable garments. However, mixed media of any type tend to be harder to recycle than mono materials.

UV-LED inks are still not flexible enough for some applications (especially flags), while the permanent dye inks used in industrial garment manufacture have their own environmental challenges due to heavy use of water and the electricity to heat it.

Water-based pigment inks don’t seem to scale up much beyond the on-demand garment sector. Direct-to-film transfers for garments are fast becoming popular as an alternative to vinyl graphics and screen print. They use a plastic carrier film, which stays at the print site after use so can be disposed of responsibly. Paper based transfer carriers may be greener, though watch out for coatings that help the release process.

Aqueous resin emulsion inks typified by HP’s Latex will work with natural textiles, though they need quite a lot of heat energy and don’t have the durability of dyes.

In the end, dye sublimation may still be the most appropriate choice for soft signage and other textile applications, even on environmental grounds. OK, polyester is a fossil fuel plastic and the sublimation process needs heat, but the image is then permanent and last for years, while PE is recyclable as long as you don’t want pristine white at the end.

Engaging in the circular economy

The circular economy concept emphasises reducing waste, recovering materials, and recycling them after use. Despite the limited control over end-of-life processes, printers and sign installers can play a crucial role in fostering a circular economy approach.

They may be able to collaborate with clients that have their own end-of-life policies, as well as waste management companies, and recycling facilities to establish systems for material recovery and recycling. Clients need to be encouraged to dispose of used signage proper sustainably, with recycling where technically feasible.

Partnering with sustainable suppliers:

Selecting suppliers who prioritise sustainability is another effective strategy. Work with suppliers committed to reducing plastic waste and offering eco-friendly alternatives.

For example in the UK, the self-adhesive media maker Metamark has introduced a certified and fully audited process for returning and recycling its materials after use. It calls this MetaStream and it covers both the vinyl materials and paper release liners. Returned paper is recycled for re-use as printable products, while vinyl elements are downcycled into other plastic goods that can themselves be recycled time and time again. Nothing is buried or burnt, says Metamark.

A small charge is made at the point of collection which is offset by reduced costs of conventional disposal to landfill or similar.

Iain Wallace is the programme’s architect and its commercial lead. He says: “We were aware that significant amounts of self-adhesive vinyl share a destiny in either incineration waste-streams or landfill sites, and that included waste from our own production. We established a zero-to-landfill programme and devised MetaStream initially to get us to zero.”

Initially this was offered to larger brand and fleet owning customers with the systems in place to track the use of such materials, and in turn help their customers reduce their environmental impact. The company has now extended the scheme to a wider audience through the handy sized Grab Bag, which requires a minimum of 300kg of either film or liner per bag, within the collection period.

“Customer reaction has been immediate and enthusiastic,” says Wallace. “Our plan for MetaStream now includes taking it to those of our customers who are lower volume users and giving it an international footprint. We’re also working on carbon offsetting initiatives.”

Metamark has also introduced MD-E2, a PVC-free material for shorter term applications. This can also be recycled via MetaStream. The main emphasis though is on MetaStream handing proven materials, such as vinyl, that the industry has been using for many years.

Alternative adhesive

Environmental impact isn’t just about what plastics are used, either. Another UK self-adhesive media manufacturing company, Nu-Coat in Wales, uses the same plastic base materials as everybody else, but it has developed a new energy-efficient adhesive application process.

Nu-Coat was set up in 2018 and has now achieved certified carbon neutrality (to the UK’s PAS2060-2014), which it believes is a world first for self-adhesive manufacture. It has an ultimate goal of becoming net zero.

Its sign media includes coloured, metallised and etched films up to 1,650mm wide. The range includes solvent, latex and UV printable PVC and non-PVC products, with matching finishing laminates. While it uses the same plastic base materials as everybody else, it has developed a new energy-efficient adhesive application process.

Instead of using either conventional solvent or water-based adhesives (which both need a lot of heat energy in manufacture), it applies a liquified adhesive that is cured by cool UV-LED lamps. There are no VOC emissions, unlike solvent adhesives.

Managing director Chris Martin says: “From the inception stage, we wanted a clean adhesive coating technology that would match up in performance to the more traditional solvent coating technologies, with no VOCs in production and without the use of fossil fuels. Our UV-cured adhesive performance is generally equally matched to solvent-based adhesive without the harmful solvent.”

On the other hand he admits that it’s not a completely “green” media, mainly because it still has to use siliconized release paper that’s the same as solvent or water-based adhesive media. This is harder to recycle, though some specialists will handle it.

Maximising materials

Planning is important for minimising waste, which makes sense at all commercial levels, not just environmental. Automated job management, multi-job ganging, step and repeat and nesting systems are all well established and can maximise the use of media on the printer, with as little as possible waste material between the pieces. There’s also an obvious cost benefit in this.

Educating clients and end-users

Education plays a vital role in reducing plastic waste. You can inform clients and end-users about the environmental impact of different signage materials and the importance of responsible disposal. Encourage them to choose sustainable options and provide them with guidance on proper disposal . Raise awareness about the benefits of the circular economy and the potential for recovering and recycling printed materials.

Conclusion

Reducing plastic usage and waste in printed signage requires a multi-faceted approach that takes in material choices, printing practices, education, and collaboration throughout the supply chain.

Embracing the circular economy concept (where available) and exploring alternative materials, such as compostable options and woven textiles, can reduce environmental impact. Although the main challenges concern end-of-life processes, these can be opportunities as well as challenges, with potential for forming partnerships to explore extended producer as well as end user responsibility and exploring upcycling opportunities contribute to a more sustainable future. By collectively embracing these strategies, over time they can make a tangible contribution to reducing plastics usage and moving towards a greener and more responsible industry.