Rob Fletcher speaks to The Muddy Merch Co who specialises in creating custom leather hat patches for a variety of clients. With this unique offering, providing personalisation has opened new markets for this company.

Much of the personalisation work available to print service providers (PSPs) is print based. Be this simple t-shirt designs, coffee mugs, key rings or greetings cards, PSPs have the capabilities to turn round personalised products efficiently and professionally.

However, this has led to increased competition in the sector, with print companies having to work harder to stand out in a crowded marketplace and differentiate themselves from the many other specialists in this area.

One way of doing this is to look outside of the traditional print sector and consider how you can use your specialist print skills to take on other work that is not necessarily printed, but has strong links to the market and is not unrealistic for print companies to think about taking on.

Step forward The Muddy Merch Co., a company based in Oregon in the US that specialises in creating custom leather hat patches for all manner of clients. The business only began life in 2019 but has gone from strength to strength as interest in its somewhat unique offering has grown, not only in Oregon but further afield in other states.

The company is run by husband-and-wife team Kristy and Greg Barton, who started out by creating custom products such as baseball caps and beanies from the corner of their garage. The business then relocated to a retail space in downtown Redmond, Oregon, and most recently upsized again to a larger facility to satisfy increasing demand for services.

Patches were previously outsourced to a local laser engraver but are now done in house. However, when it came to applying them to the actual hats, this is where the business was struggling. It would glue and stitch on each patch, applying contact cement or spray-on adhesive to each patch. This process proved incredibly time-consuming and put limitations on production capacity, leading to The Muddy Merch Co. seeking an alternative.

Crossing over into new market.

This is where the link to print comes into play and could very much offer food for thought to those seeking new opportunities in promotional and personalisation work. Rather than keeping with the older, slow process, The Muddy Merch Co. went in search of a more efficient method, trying out several adhesives in the process.

The Muddy Merch Co. eventually settled on Drytac MultiTac, a high tack acrylic adhesive that is most commonly used for mounting graphics to difficult or irregular surfaces. The bond on the product helps graphics to adhere to trickly surfaces, allowing users to provide effective solutions in challenging jobs.

While The Muddy Merch Co. is not applying printed graphics, it is now using a method that is popular with PSPs to apply the engraved patches to hats. Could serve as inspiration to companies seeking new opportunities outside print? Gary Barker, national sales manager at Digital Technology Group, the approved Drytac distributor that supplied the products, thinks so.

“We strive to bring together great manufacturers with innovative products – such as Drytac and its MultiTac adhesive – and our customers such as Muddy Merch Co.,” Barker said. “By combining these strengths, they can deliver innovation and excellence to the marketplace.”

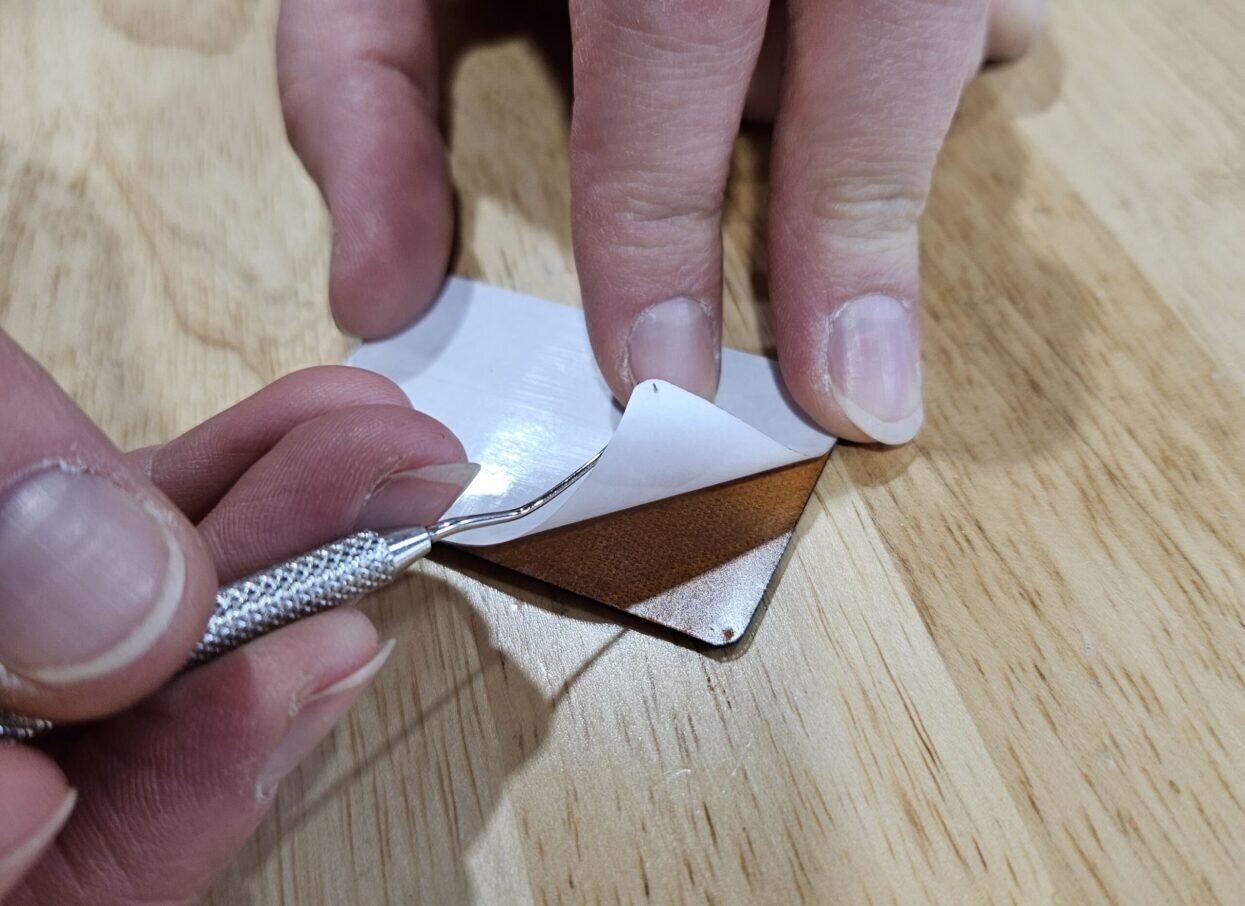

Caption: The company uses materials and methods traditionally associated with applying graphics

Think outside the box

So, how does the process work? The Muddy Merch Co. rolls out the Drytac adhesive on one of its workbenches and then rolls a large piece of leather out on top. Staff trim the edges and firmly adhere the adhesive to the back side of the leather. The leather is then cut into large squares to fit onto its laser engraver, where its engraves and cuts out individual patches ready to be applied to the front of hats and beanies.

Kirsty Barton from The Muddy Merch Co. explained: “We use a hat press, without turning on the heat, to firmly press each patch onto the hats, and then stitch them on with our industrial sewing machines – a 227R Consew and a Cobra Class 26.

“Using a pressure sensitive, rather than a heat-activated, adhesive allows us to temporarily hold the patches firmly in place so that they don’t shift or pucker while we stitch them on. Not using heat also means we don’t damage the leather.

“We knew our application wasn’t what the product has been historically used for, but it ended up being the absolutely perfect solution for us. MultiTac was available on a roll, which was the perfect size for our leather, and had a composition that allowed us to run it through the laser.”

Barton added that the process has allowed The Muddy Merch Co. to significantly expand its customer base.

“The discovery of MultiTac couldn’t have come at a better time,” Barton said. “Shortly after opening the new shop, the business really took off. Using the Drytac adhesive allowed us to produce large quantities of patches that came off the laser engraver with adhesive already applied.

“Because MultiTac also comes with a transfer paper, we were able to store and stack the patches without anything sticking together and move them through the next step of production – stitching them onto the hat – as time allowed.

“We serve a variety of clients, all the way from breweries to private weddings; local construction companies to large deck builders; and family reunions to large manufacturing companies. Basically, for anyone that has a design or logo that they would like engraved into a leather patch and stitched onto a hat, we are here to help!

“We’ve carried out projects all the way from a single hat with a custom design, up to over 1,000 hats with a business’s logo. It’s always fun for us to see our work either walking around town locally or travelling the world in people’s social media posts.”

For further insight into the type of work – both print and non-traditional – within the wider sector, why not visit the Personalisation Experience 2024? Taking place alongside the main FESPA Global Print Expo 2024 in Amsterdam, the Netherlands from 19-22 March, the event will showcase the latest developments and technology in this busy market.

Personalisation Experience will return for a second year at the RAI Amsterdam, Netherlands from 19th – 22nd March 2024. Visitors will have the opportunity to hear from leading minds and innovators sharing knowledge and experiences, see the latest developments and technology in personalised print solutions and network with those looking to help you grow your business. Register here to visit and use promo code PEXJ402 to get a 55 euros discount.