Large format printing backlit applications are among the most spectacular applications in digital printing. Sonja Angerer shares the latest technologies around this sector.

Whether as a banner for the Christmas special sale or a menu above the counter in a fast-food restaurant: backlit displays always attract attention. The colours and text are brighter and more vibrant when they are illuminated from the back.

Usually, a backlit display looks like a digital screen from a distance. However, compared to digital signage, print uses much less resources. This is another reason why backlit applications are one of the most popular applications in large format printing.

A backlit application consists of 3 parts:

- Print on film or textile

- Light fixture

- Profiles for the construction

Textile for backlit applications

- translucent

- able to be illuminated without shadows

- durable and odourless

Printing substrates for backlit applications are available as textile surfaces, for example from Dynajet or Berger Textiles. It is usually densely woven polyester, but occasionally fabrics are also made of PET or recycled PET (rPET). The typical weight is approx. 200 g/sqm, the translucency is approx. 50%.

Stretch cloth textiles are usually printed with UV-curable inks using the direct printing process. However, many products available on the market can also be used with (Eco) Solvent or Latex inks.

Polyester textiles are also ideal for sublimation transfer printing. When transferring the motif from the transfer paper to the fabric, the pigments embed themselves deep into the fabric. The colours are therefore durable and brilliant, but for indoor use only. Additives in the inks disappear during transfer, so the finished prints remain odourless even when heated by the backlit lamps. Textile backlit substrates for transfer printing are usually available up to 3.20 m wide.

large format printing backlit applications in the outdoors are usually installed with the help of a cherry picker.

Image: S. Angerer

Films for light boxes

For very large applications, long-term advertising and backlit posters in the outdoors, special backlit substrates, e.g. from Heytex are common. They are made with a polyester backing fabric that is thickly coated with PVC. As a result, the textile structure is covered, and the translucency is around 30%. Backlit films are between 500 and 700 g/sqm in weight. Therefore, they are not sewn together, but welded. They are typically available as roll stock in widths of 3.20 and 5 m for direct printing with all common inkjet technologies.

Backlit film, such as offered by Sihl, does not require a textile base. For this reason, the polyester media for UV, latex printing and UV gel technology achieves a transparency of up to approximately 75% at 200 to 300 g/sqm. The films remain very flat and are mainly used for Citylight posters (CLPs). For CLPs, also a special paper with about 150 gsm is very common.

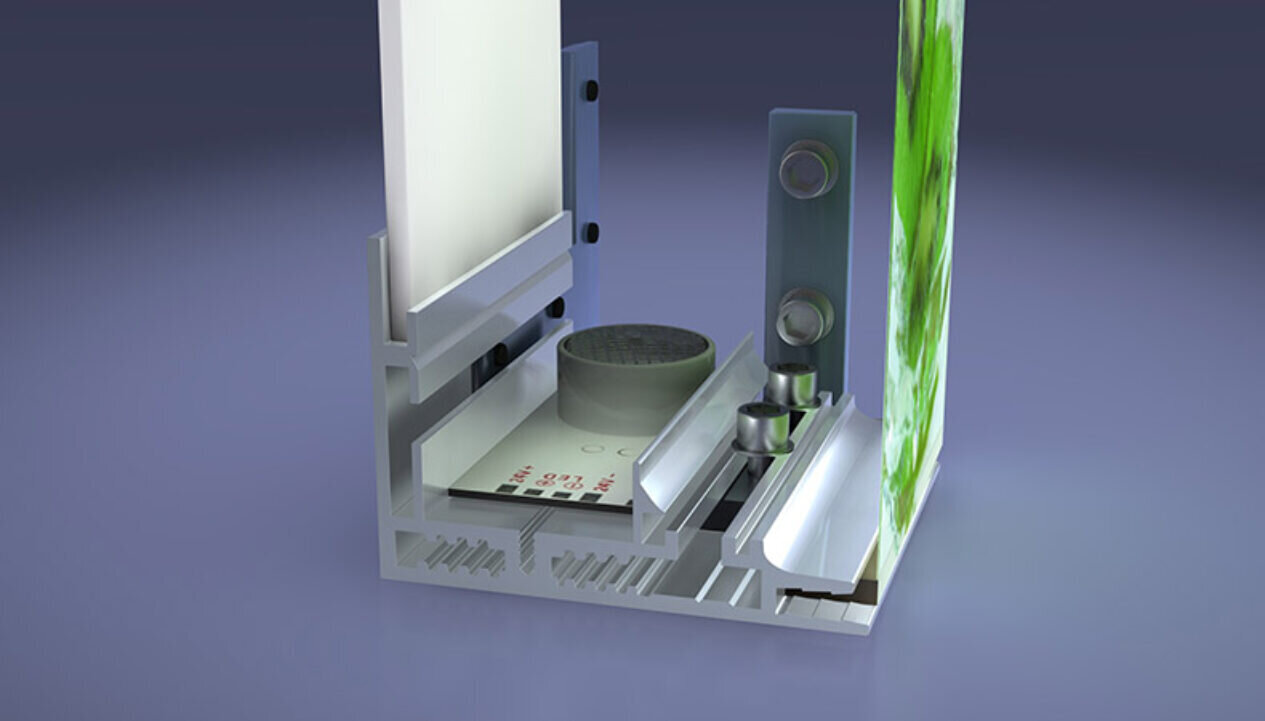

TF-70 profile system from Licht-Konzept & Form. Centre: aluminium heat sink for high-power LEDs.

Image: Light Concept & Form

From printing to backlit application

Backlit applications are illuminated from behind, most often in a type of light box. How the print has to be finished depends on the type of light box. Fabrics are typically fitted with approximately 1.5 cm wide flat piping sewn to its edges. As a result, the slightly stretchy fabric can be inserted quickly and easily into the light box.

Because no tools are required for this and the motif change is easy even for a layperson, textile-fronted backlit displays are common for POS applications. Textile prints for lightboxes are also lightweight and do not wrinkle easily, so they don’t have to be sent rolled up.

Backlit films for outdoor use at typically fitted with eyelets to fit a rope, with a foldable frame front to cover the fastening. Mounting is conducted by professionals with the help of a lifting platform or a cherry picker, as the prints can be very large and heavy. Foils and papers for Citylight posters are usually clamped into place, so they only need to be cut to size.

Light boxes are sometimes used for interior decoration as well.

Image: S. Angerer

Building materials for light boxes

For a custom-made light box, you need aluminium profiles for the housing and a light system. Often, a special diffuser lens is used to provide shadowless light. This is especially important with neon tubes for backlighting. Today, most applications have been converted to energy-saving LEDs. These are available through many suppliers.

Many small LEDs enable very uniform illumination from the edges of the lightbox or as a grid. They generate less heat than Neon lights. With very strong LEDs with high luminosity, heat though can still be a problem. For this reason, Licht-Konzept & Form offers its trademark TF profile systems with integrated heat sinks. The CE/EMC-certified frames are manufactured to the customer’s requirements. They are fitted with high-performance LEDs including a power supply.

Sign makers who have their own metal workshop can obtain various profile systems as well as accessories from suppliers such as EPS Systems or Sign-Ware to build backlit application frames. However, most manufacturers also offer made to order backlit frames including wiring.

Backlit applications as a market opportunity

Backlit applications are still popular, especially at the POS and in trade fair construction. It is true that the boom that has resulted from the conversion of existing installations to LED technology for quite some time now is likely to come to an end soon. However, most experts expect the order situation for light boxes and backlit systems to remain solid for years to come.

Discover the latest innovations in signage at European Sign Expo 2024 Europe’s leading signage and visual communications exhibition. Taking place from 19th – 22nd March 2024 at RAI Amsterdam, Netherlands. Register to visit here and use promo code ESEJ403 to receive a discount of 30 euros.