Kornit Digital and Fashion Enter LTD launch the Fashtech Innovation Centre in the heart of London. Debbie McKeegan shares how Kornit Digital have successfully created a smart manufacturing hub powered by the latest digital technologies in sync with decades of sewn production skills. The project delivers Smart manufacturing, and signposts a new era of sustainable production on-demand.

When we all talk of nearshore or close proximity production, there is always an unspoken truth. Sewn manufacturing (or CMT to those within the industry) – and its local availability. Textiles once printed, are always cut and sewn into a final product. Supply chain challenges of the last two years have exposed a sewn skills gap, and further highlighted a significant lack of manufacturing knowledge readily available here in the UK – making the reshoring of sewn goods in any volume a difficult proposition.

It’s a problem of the West and an issue of our own making. However, there are exceptions. The textile industry historically would provide a wide demographic of skills in a manufacturing zone, geographically. Leicester is a good example. And there are still industrial sewing communities. Communities that are often hidden in traditional businesses (fashion and home furnishings) that have survived the last 30 years, a difficult time, when volume production shifted offshore into the East.

The skills are here in the UK – and its thanks to individuals like Jenny Holloway and the team at Fashion-Enter LTD that those precious production skills are not lost. In fact, they are being nurtured, and channelled into new production methods, new business models and smart manufacturing hubs. Add in digital textile printing on-demand from Kornit Digital and you hit the sweet spot – that unites the supply chain – and ultimately delivers on-demand manufacturing for printed and sewn products.

Kornit Digital and Fashion Enter LTD launch the Fashtech Innovation Centre in the heart of London. It’s a bold move, and a smart move. One that brings together two change makers in one location.

Jenny Holloway incorporated Fashion-Enter Ltd in 2006 as a not-for-profit social enterprise that has two aims; to provide outstanding British made quality garment production and to be a centre of excellence for training and development.

To date there are over 200 employees across four locations in Haringey, Islington, Leicester and Wales. Fashion Enter produces up to 30,000 quality garments a week from two factories in London and Wales, Newtown. Clients include ASOS, N Brown, I Saw It First and Risdon and Risdon. Fashion Enter is the only UK company that has a leading status in the ethical and technical Fast Forward audit and is also SMETA audited.

Established in 2008 the Fashion Studio creates first patterns, toiling, seals, grades and short run production from 1 unit to 300 units. The service also provides sampling without the construction of patterns e.g., press samples.

Jenny Holloway incorporated Fashion-Enter Ltd in 2006 as a not-for-profit social enterprise that has two aims; to provide outstanding British made quality garment production and to be a centre of excellence for training and development.

Their training academy teaches and utilises CAD CAM for many aspects of design selection, marking, grading and production. 3D visualisation is increasingly used for selection purposes, although sewn samples are in the main still required by the buyers.

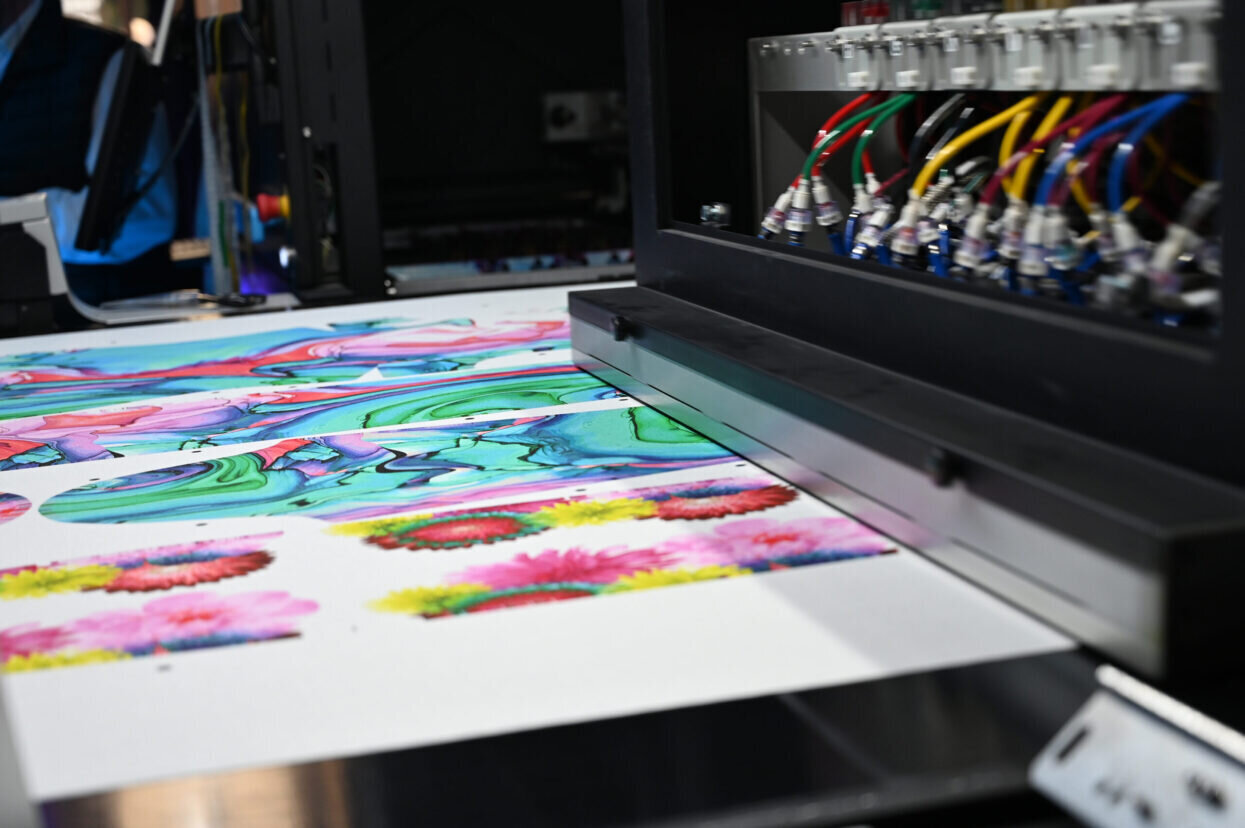

The addition of Kornit Digital textile printing technology and this industrial collaboration is an important step and offers the industry a benchmark for smart manufacturing.

Speaking at the launch of the Kornit Digital Fashtech Innovation centre Jenny commented “This Innovation Centre makes it possible to capture the full, end-to-end production process in one, single location,” said Jenny Holloway, Chief Executive Officer, Fashion-Enter. “The beauty of having print on demand means there are no minimums, so we can make one garment, or we can make up to 30,000 garments a week from all locations at the same fixed cost. Here, we can also train future generations on the right way of producing garments for today, responsive to demand, with minimal waste—ethical and sustainable. This is the future of fashion and textiles.”

Kornit Digital is a worldwide market leader in sustainable, fashion on-demand, digital and textile production technologies. The company is writing the operating system for fashion with end-to-end solutions including digital printing systems, inks, consumables, and an entire global ecosystem that manages workflows and fulfilment. Headquartered in Israel with offices in the USA, Europe, and Asia Pacific, Kornit Digital serves customers in more than 100 countries and states worldwide.

“We are pleased to put these technologies on full display in our new joint Fashtech Innovation Centre and bring on-demand manufacturing back home to the UK” commented Chris Govier of Kornit Digital.

“As our partner ecosystem continues to grow globally by aligning with such leaders as Fashion Enter, companies are realizing just how powerful sustainable, on-demand digital production can be and the countless inherent benefits it provides,” said Chris Govier, President Europe, Middle East, and Africa, Kornit Digital.

“We are pleased to put these technologies on full display in our new joint Fashtech Innovation Centre and bring on-demand manufacturing back home to the UK. Whether you’re a brand, apparel provider, custom fabric fulfiller, or creative designer wondering how to handle the next major market disruption, grow product lines, create a more eco-responsible and accountable production floor – or just want to waste less – the Innovation Centre will help you achieve these goals.”