The topic of ISO standards is pretty dreary, but it’s a subject that can make a difference to the success of your wide format projects.

Standards published by the International Standards Organisation are created and developed by people like you. It’s a cooperative and consensual process rooted in local groups who come up with ideas for how something can benefit from standardisation, such as dimensions in building or data formats.

People notice how common worries might be resolved with a standardised process or set of requirements. Someone comes up with an idea for how to simplify fixing a problem, they share it, refine and improve it, and ISO eventually publishes a document. Then anyone can use that standard and apply it for their circumstances.

That’s a very simplistic narrative to describe what is actually a convoluted and often tedious process. For ISO consensus is all, but getting everyone in all participating nations to agree with a given solution takes time. It also takes patience. Lots and lots and lots of patience.

Why should I care?

So why should this matter to you, as you start planning your wild format printing project? For a start it means that you can be reassured that ISO standards are available to help the folks doing your production to get it right. But standards are there for you too, not just for the companies offering services.

ISO 9001 – Quality Management Systems

You can use ISO 9001 principles in your work. Plan what you want to do, do it and then review how things went. If there are parts of your plan and its execution that could be improved, weave the improvements in for your next wild format project.

ISO 9001 outlines requirements for quality management systems and is ISO’s bestseller, so you see this number all over the place. From plumbers and bricklayers to high street brands, everyone can benefit from ISO 9001. It’s based on the brilliant observation that you can make any process better, if you keep reviewing and improving it, so that it continually evolves.

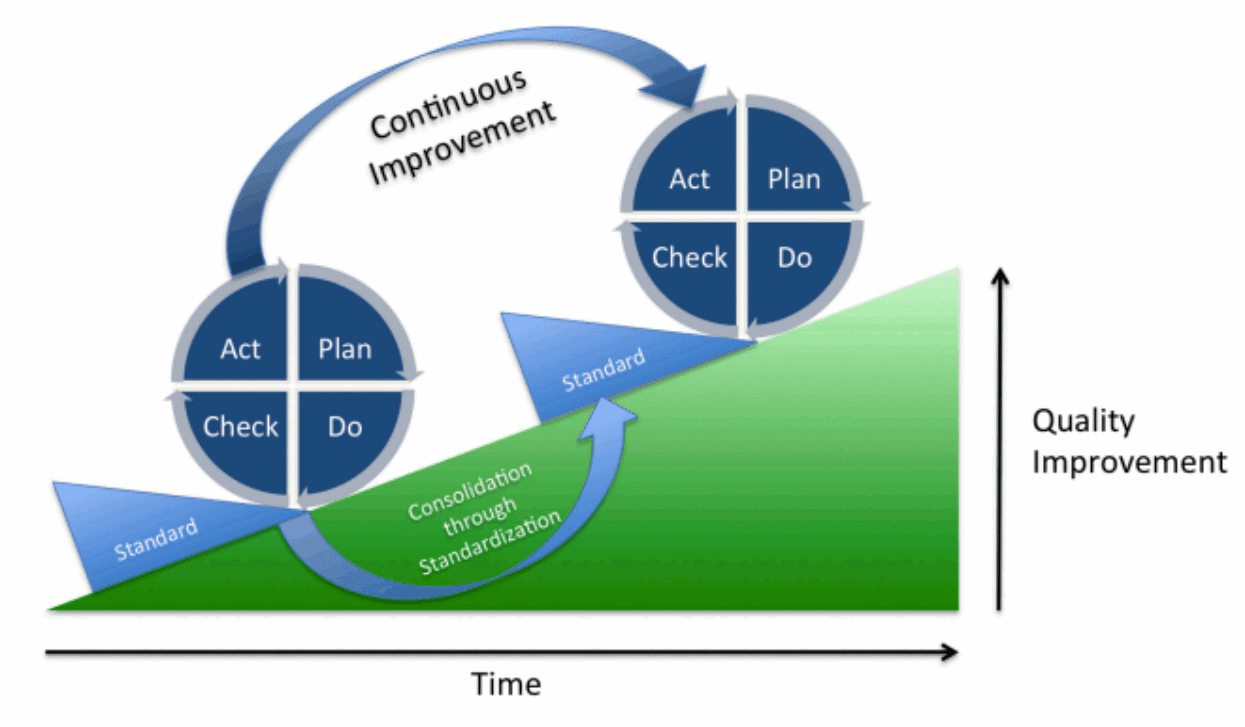

The underlying principle of ISO 9001 is the cycle of plan, do, check and act. You start by working out what you want to achieve and you come up with a plan for achieving it. You then follow the plan, check what things have worked and what things haven’t and then figure out a way to improve the plan for the next project.

The basic principle is simple enough, but companies who can prove compliance to ISO 9001 will have jumped through a couple more hoops. The first and most important is that everything they do is based on facts, normally based on proper measurements and analysis.

Actions taken, checks made and approvals should be documented so you can track that a product has been made according to specifications. They can also demonstrate that they have management structures in place to support it. And they will have documented management engagement and risk assessment processes.

For a company it’s about good business practices, so that customers like you don’t have to bother with the details. All you need to know is that a business achieving ISO 9001 has a mark of quality, a gold star double tick proving their competence.

If a company claims that it delivers superior print quality, that ISO 9001 badge confirms that it really can. If it cannot, the certification could be withdrawn which would be bad news for that printing company’s marketing department.

Companies use ISO 9001 to show that they can consistently deliver products and services that meet legal requirements. Independent auditors check that companies have systems in place to control the four stages of the cycle, and that processes continuously improve. If your print service provider has an ISO 9001 certificate you can be reasonably confident that the work they do for you will be up to scratch.

If you want even more security, ask your print service provider about ISO 12647 which defines the printing condition parameters for various print processes. This multi-part standard assures colour print output quality levels according to the printing method, say screen printing or offset, often the reference for digital printing quality. ISO technical committee working groups have recently started work on a part for printing on metal.

Liberation and Release

If you’re not already bored to tears but instead find this ISO standards stuff interesting, there are a couple more you might want to consider for your own work. You can shell out on these documents or ask your service provider about them, a much better option since they are free. They are ISO 15076 Image technology colour management (ICC profiles) and ISO 15930 Pre-press digital data exchange (PDF/X).

In fact, it’s very likely that you already use both of these without realising it. Software developers such as Adobe, Fujifilm and HP are heavily involved in ISO standards development work so they make sure that their software products include tools that comply with the standards. ISO 15076 standardises ICC profiles, and you are probably familiar with them even if you aren’t entirely certain what they are.

ISO 15076 – ICC Profiles

An ICC profile is a data set that characterises a colour input or output device, such as a monitor or a printer. It’s a digital summary of how a device presents colour, say on screen or in print. A monitor profile for instance will specify the brightness, contrast and red, green and blue values for a particular monitor.

Clever mathematics calculate how to present the colour information on another device, using this information to make sure that colours look the same on both devices. This can all get a bit technical, but you don’t need to worry about it because colour management scientists have done the worrying for you.

ICC profiles are available to you in PhotoShop and Illustrator, plus pretty much all functional colour and content layout tools. ISO 15930 – PDF/X ISO 15930, another multi-part standard, is also implemented in your content creation tools, since it’s the standard that simplifies PDF data exchange.

As you know, PDF is a universal file interchange mechanism. It makes it possible to share files across operating systems and devices, so it has become the format of choice in the graphic arts for file sharing. ISO 15930 was developed to make PDF processing a bit more consistent and reliable for different types of print workflows.

When you create your PDFs ready to send them off to production you can choose how that PDF is written. If you choose to create a PDF/X file you’ve got a better chance that your file will pass through the production process without incident.

ISO standards sound dull but they really can be useful for your work. Software developers working in the graphics industry have implemented many of them already, making it much simpler for end users to create print-ready files. What matters more is that software developers and service providers understand how to implement them in their particular situation.

This brings us back to ISO 9001 for quality management systems. It isn’t enough to implement the Plan-Do-Check-Act cycle in the administrative parts of the business. Ideally print service providers should be applying the ISO 9001 principles to their production processes as well. If they are doing this you can be certain that whatever form your wild format project takes, it will be well produced.