Agfa Graphics releases PressTune and InkTune

Afgha Graphics announced the release of their PressTune and InkTune software to lower production costs. PressTune and InkTune are part of Afgha Graphics’ ECO³ offering and provides print houses control over all printing elements whilst simultaneously reducing production costs.

ECO³

InkTune and PressTune are crucial elements of Agfa Graphics’ ECO³ program. In designing and creating solutions based on hardware, software and consumables, Agfa Graphics focuses on ecology, economy, and extra convenience (ECO³) to make prepress and printing operations cleaner, more cost-effective and easier to manage and maintain. The ECO³ solutions drive extra value to printing businesses.

InkTune: cost savings plus quality boosts

Building on grey component replacement (GCR) technology, InkTune dynamically substitutes CMY inks with black ink. As an intuitive software solution that is fully integrated into the prepress workflow, InkTune uses Agfa unique technology such as Dynamic Ink Limit Control and Dynamic Device Link Generation to maximize ink reduction up to 30%, while maintaining color fidelity. The reduction of ink not only has a positive cost savings impact, it also increases overall production efficiency as the drying time is reduced. Furthermore, quality levels increase as rosette structures disappear and color deviations become less visible.

“InkTune eliminates the choice between the reduction of ink, time, and drying powder on the one hand, and high-quality prints on the other hand. Customers can achieve all these benefits through the software’s built-in intelligent adjustment of ink consumption. InkTune allows them to shorten press setup times, as well as to cut costs of all print-related resources, achieving the lowest total cost of ownership on the market. It is easily set up and requires no additional investment in training or hardware,” asserts Erik Peeters, Global Marketing Manager Software Solutions at Agfa Graphics.

PressTune: a new benchmark in smart print process control

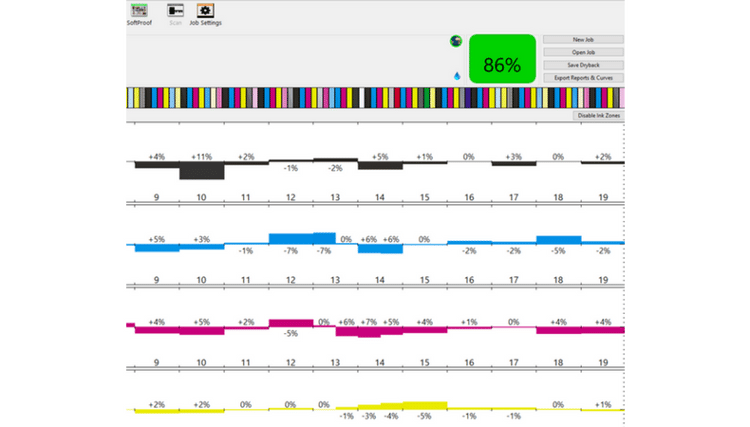

As a print production tool, PressTune drives consistency, productivity and the ability to print to exacting standards. As the required print quality standard is reached faster by means of dynamic ink density adjustment and a data-driven scoring mechanism incorporating dry-back compensation, make-ready times get reduced by up to 40% – which in turn leads to less waste.

Through intelligent analytics capabilities applied to print and color data obtained from the press, PressTune also reports in real time across printing technologies to each stakeholder, for full transparency of the print production process. It enables issue identification and optimized press maintenance scheduling. Even more, the solution’s easy-to-read dashboard makes it simple to generate print quality reports for brand owners in packaging and commercial print and allows for remote quality assurance.

“Together, PressTune and InkTune enable significant cost savings by reducing ink use, boosting quality and accelerating your production workflow,” continues Erik Peeters. “In fact, PressTune provides InkTune with the perfect foundation to optimize ink consumption by delivering quality consistence. Both PressTune and InkTune are central to our ECO³ offering, embodying sustainable innovation that focuses on ecology, economy, and extra convenience for the customer.”

Complementary solutions in action

Imprimeries et Editions Henry, a print house in Montreuil-sur-Mer with a 120-year history, recently worked alongside consultants from Agfa Graphics to take its print processes to the next level. Already relying on an Avalon system, Azura plates and Agfa Graphics’ Apogee workflow, the firm recently installed both PressTune and InkTune.

“PressTune and InkTune have enabled us to obtain a higher consistency throughout our print runs,” says Marc Henry at Imprimeries et Editions Henry. “We have reduced our make-ready times, we use less paper and ink, and we can adapt printer calibration curves according to paper, print job or customer-specific demands. Agfa Graphics’ solutions have brought us a more convenient way of working.”

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The power of digital design tools in screen printing

James Gatica shares how the combination of traditional screen-printing techniques with cutting-edge digital design tools is revolutionising the way designers conceptualise and produce custom decorative pieces.

Key trends and market shifts on Personalisation and Sportswear with Epson

Debbie McKeegan speaks to Duncan Ferguson, VP of Commercial and Industrial Printing at Epson Europe about the market shifts and current trends around personalisation. Duncan shares the key trend of merging both fashion and sportswear.