FESPA’s Textile Ambassador, Debbie McKeegan speaks to 5 industry specialists from Stahls’ UK & Europe, Kornit Digital, Antigro Designer, MS & JK Group and JK Group about the opportunities, challenges and solutions currently available for on-demand digitally printed textile production.

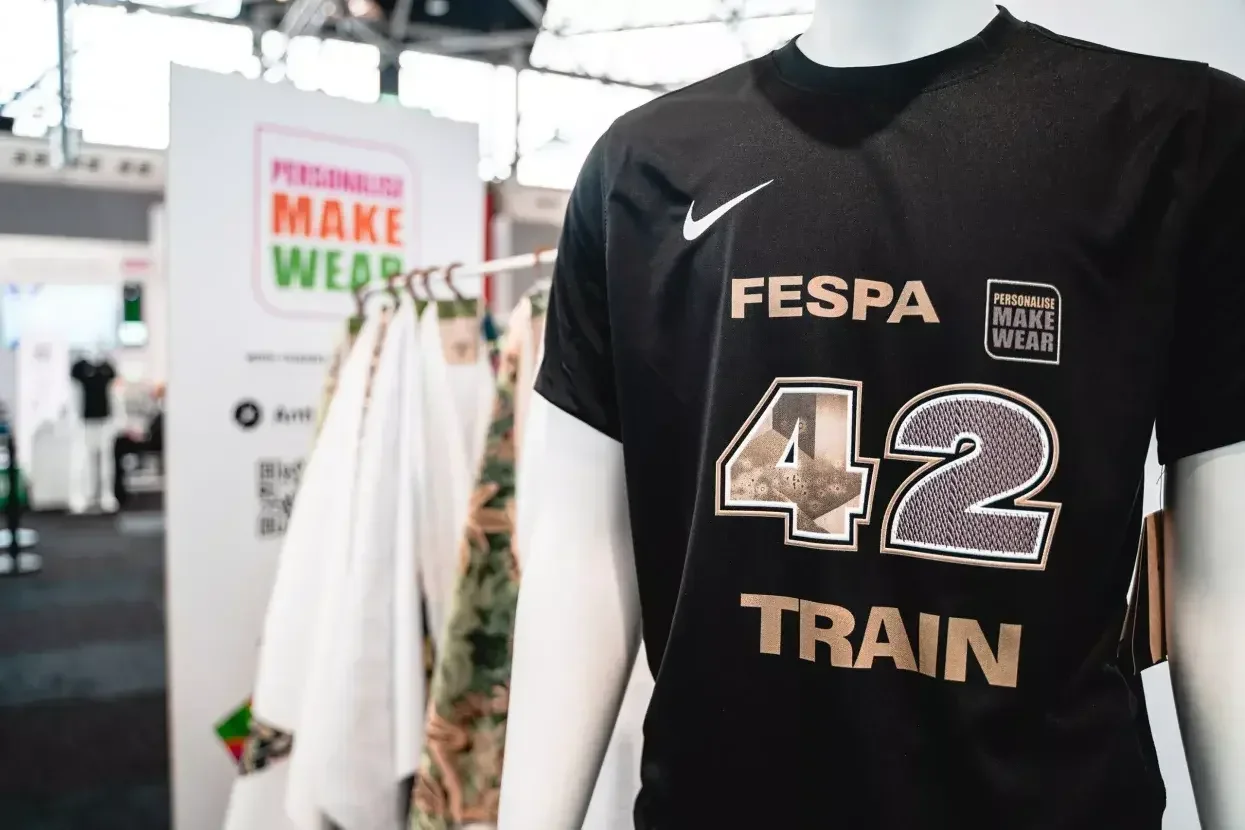

Held at the recent FESPA Global Expo in Amsterdam, the “Personalise Make Wear” feature showcased a live custom-built, end-to-end Smart Factory that manufactured customised, personalised sportswear on-demand. The feature signposted the future of manufacturing as the industry shifts to sustainable, environmental production.

During the show exhibitors and industry experts worked side-by-side to explore and demonstrate the disruptive, transformative technologies now available for digital manufacture. Hosted by FESPA Textile Ambassador, Debbie McKeegan visitors were able to join and experience expert tours and live demonstrations from the many industry experts and application specialists on-site for the duration of the show.

Each day specialists gathered at 13:00pm for a Fire-side chat. The excepts below detail the 3rd of 4 conversations hosted by Debbie McKeegan with PMW partners, special guests and exhibitors in residence.

In conversation the panel centred their collective focus on Sportswear to explore the opportunities, challenges and solutions now available for on-demand digitally printed textile production. The talk explores the implementation of disruptive technologies for the sports sector and the market shifts that will force systemic behavioural change for the supply chain. Below we detail the key takeaways from our conversation. You can listen to the 29:00 min audio podcast here.

Special guests:

- Andy Rogers, Marketing Director at Stahls’ UK & Europe

- Anna Holmes, Business and Development Manager, Sportswear & Athleisure, Kornit Digital

- Waclaw Mostowski, CRO, Antigro Designer

- Matteo Forte – Sr Consumer, Product Marketing Manager, MS & JK Group

- Davide Dragoni, R&D Digital Inks at JK Group

Digital Transformation in Production

Digital transformation plays a pivotal role in modernising the production processes routinely used by the Sportswear industry. In time, leading to enhanced operational efficiency, significant cost savings, and a reduction in time-to-market. The panel highlighted that digital print technologies now enable the creation of complex designs and patterns, offering a competitive advantage to manufacturers willing to embrace innovation. Adopting such technologies facilitates the production of bespoke sportswear and products that meet customer demands for unique and high-quality products.

Embedding Stories in Products

Storytelling is key. Embedding data and narratives directly into products is already revolutionising the customer experience. Technologies like QR codes and blockchain enable unparalleled engagement and a deeper connection between the brands and the consumer. For example, a QR code on sportswear garment can share the inspiration behind its design, the ethical sourcing of its materials, and its manufacturing journey. All of which fosters trust and promotes customer loyalty through transparent and engaging storytelling.

Streamlining Production for Efficiency

Efficient production processes are crucial for a successful shift to personalised manufacturing. Integrated supply chain management systems and predictive analytics can provide visibility and control over production. These tools forecast demand, monitor equipment status, and optimise resource use, leading to reduced downtime and waste. Modular production enhances flexibility, and manufacturing agility. These advancements ensure manufacturers can meet customer demands efficiently, whilst boosting productivity and maintaining a responsive manufacturing environment.

Embracing Sustainability

The sportswear manufacturing sector is witnessing a significant shift towards sustainability and customer-centric models. Embracing eco-friendly materials such as recycled polyester and biodegradable fibres

reduces the industry’s carbon footprint. Energy-efficient production processes further contribute to environmental sustainability.

The Future of Sportswear Manufacturing

As the industry evolves, manufacturers who adopt digital process to reduce their environmental impact will lead the way. Personalised, high-performing products that adhere to ethical and sustainable practices resonate with the modern consumer. The convergence of technology, consumer demand, and ethical considerations offers new growth opportunities and positions Sports brands to thrive.

In summary: The emphasis is clear – the industry needs to embrace innovation, sustainability, and customer engagement to conquer the future. The talk delivered not just insights but also inspiration for all those ready to push the boundaries and redefine the sportswear industry and if that sounds like you, then you can listen to the podcast here

Sportswear Pro will return in 2026. To discover the latest content that covers a wide range of sectors including personalisation and sportswear sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.