Sonja Angerer provides a guide for designers on creating perfect car wraps, emphasizing the need to avoid common mistakes. Key steps include selecting the appropriate vinyl or polyurethane film, considering the design’s environmental impact, focusing on a clear communication goal, and adhering to legal/technical road restrictions. Designers must also ensure high-resolution motifs fit the vehicle shape to prevent distortion.

Under #carwrapping you can find about 1.4 million posts on Instagram alone. So, it is one can conclude that car wrapping is the most popular application in digital printing and sign making today, not only for business customers, but also for end consumers.

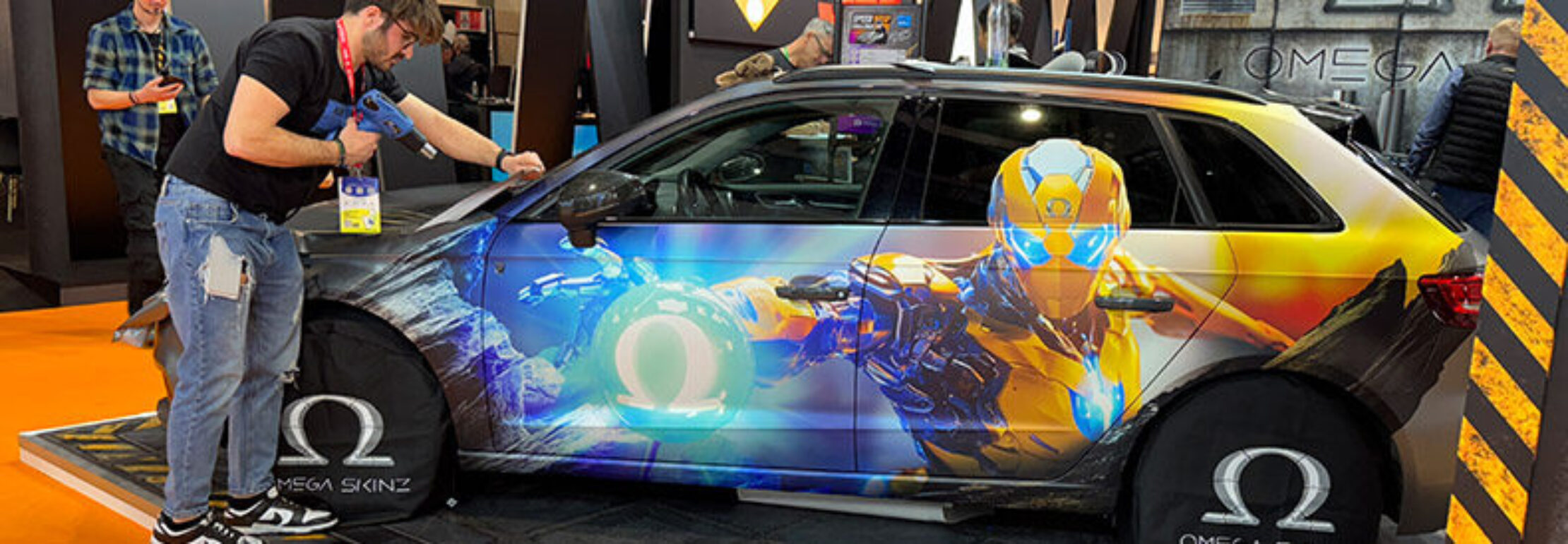

CAPTION: A good design can go a long way in making a car wrap perfect. Image Credit: Sonja Angerer

CAPTION: A good design can go a long way in making a car wrap perfect. Image Credit: Sonja Angerer

Graphic designers therefore often receive requests to create designs for vehicles for their customers or to adapt existing motifs. There are true-to-scale templates for most common vehicle types that make work much easier, e.g. from CC Vision. Mock-ups for presentations are available from Adobe Stock or Shutterstock. Nevertheless, there are a few factors that designers should keep in mind.

Choosing the right substrates

Choosing the right film is crucial. That’s why designers are encouraged to work closely with their customers to determine which substrates should be used early on. There are different types of films, each with their own advantages and disadvantages as well as with varying prices.

Vinyl films (PVC): These are the most commonly used films for car wrapping. They are durable, flexible, and available in a wide variety of colours and textures. Vinyl films are ideal for complex long-term designs as they offer good UV resistance. There is a wide range of white PVC film available for eco-solvent, UV-curing and latex inks, fine-tuned for car wrapping

Cast vinyl film by 3M, Avery, Orafol and others is required for 3D curved surfaces with rivets as well as high-quality, long-term applications. For short-term partial wraps on slightly curved surfaces, cheaper, calendared PVC film is often sufficient.

(Thermoplastic) polyurethane films (TPU / PU): These films are an alternative to PVC and are particularly resistant to scratches and chemicals. However, they are more expensive than vinyl films and require more careful application. They are available from CYS Europe and others.

CAPTION: Rear side windows may be covered if this does not hinder view. Image Credit: Sonja Angerer

CAPTION: Rear side windows may be covered if this does not hinder view. Image Credit: Sonja Angerer

Environmental impact of car wrapping

When choosing films, designers should also consider the environmental impact. Some films, especially those made of PVC, contain harmful chemicals that can be released during both production and disposal.

Therefore, many manufacturers now offer PVC film alternatives, e.g. Hexis or Arlon. Designers should explicitly suggest such products for the implementation of their designs. In many cases, end customers are not even aware of the new, less environmentally harmful products for vehicle wrapping.

But designers can do more to make car wrapping more sustainable. It is often dependent on the design, how much square meters need to be printed, and how much waste is generated. It is often possible to release great designs with significantly less substrate use by skilfully combining colour, effect and printed film.

CAPTION: Stickers on head lights are not allowed on German roads. Image Credit: Sonja Angerer

CAPTION: Stickers on head lights are not allowed on German roads. Image Credit: Sonja Angerer

Communication goals and motives

In most cases, business customers specify in the briefing which communication goal is to be achieved with the car wrapping. It makes sense to concentrate on an easy-to-grasp core message, like those on a poster, as the vehicle will often only be visible to passers-by for only a few seconds.

That’s why it’s particularly important to focus on at least one channel for easy contact, e.g. a vanity phone number, or an attractive website. For vehicle wraps commissioned by end customers, designers should also insist on a briefing.

Legal and technical framework for car wrapping

Private and commercial customers for car wrapping often do not know about the technical and legal restrictions in car wrapping. However, these can affect the design significantly. For a perfect vehicle wrap, designers should therefore educate their customer early on.

A design that is too reminiscent of the police or fire brigade can be quite problematic. But also highly reflective, noctilucent or reflection-free (Vanta Black) surfaces are usually not accepted by the authorities. Head lights and license plates are not to be wrapped at all in Germany.

However, car wraps that are available in Germany are usually not subject to registration. A wrapped vehicle must still comply with road traffic regulations, so front and side windows must not be covered at all, and rear side windows can only be covered without hindering driver’s sight. For rear windows, one-way vision film with 50% light transmission is permitted.

CAPTION: Designers suggesting the right film are helping to minimise vehicle wrapping impact on the environment. Image Credit: Sonja Angerer

CAPTION: Designers suggesting the right film are helping to minimise vehicle wrapping impact on the environment. Image Credit: Sonja Angerer

Choice of motif for the perfect car wrapping

In addition to legal and technical requirements, high-quality car wrapping design in high-resolution is crucial for success. It needs to be available in at least 210 ppi in actual printing size.

At the same time, the design must fit well with the shape of the vehicle. Important details of the motif should not be intended for strongly rounded surfaces such as fenders, as this can lead to distortion and other poor effects.

Motif parts that go over doors can also be problematic. The wrapper must go to great length to make sure no offset is visible. Despite of all the efforts, unintended funny effects are common, e. g. when only half a face is shown when the sliding door is open.

With a good design, such problems can be avoided. When designing for car wrapping, it often makes sense to create more than just a 2D digital preview on the vehicle template. If the design is to be test-wrapped on some critical parts (e.g. fender), this allows for adaptation and optimisation before film and labour time is wasted.

Planning for the perfect car wrapping

With the right materials and techniques, even less experienced designers can create impressive car wraps. However, it is important to determine a detailed briefing with the customer that already considers legal and technical restrictions. This also ensures that the job succeeds and uses as few resources as possible.