Nessan discusses how there is still a distinctive need for screen printing in today’s world. He shares the advantages of this technique and the various industrial applications it can be used for.

Anyone who has been to a Fespa show will have seen a lot of screen printing equipment, mostly demonstrating textile printing. However, screen printing is also used in a wide range of different industrial applications that are often overlooked.

The principle behind screen printing is relatively simple. It starts with a mesh screen with a reverse of the image created on the mesh, blocking the non-image areas. The ink is then pushed through the mesh to create the image, one colour at a time. Coloured images can be built up using either process colours or multiple spot colours.

The main advantage of screen printing over inkjet is that there’s a wide range of different inks available, which means that it can be used to print to many different types of materials, both rigid and flexible, regardless of the machine’s manufacturer. This can include textiles but also smooth surfaces such as glass and metal as well as wood, plastic and even paper.

Users can select an ink to deliver the characteristics required for each application, whether that’s scratch resistance or ability to withstand heat or water. Depending on the inkset, there may be a wider range of colours available for one type of ink over another.

In addition, screen printing is very well suited to coating applications including lacquers, sealants and adhesives, where it can produce a large and even coating over a wide area.

Personalisation is not generally a requirement for most industrial applications, and screen printing can be cost effective for both short batches using manual machines and long production runs with more automated screen printers. Consequently the technology is holding its own against the inkjet alternatives for many different applications.

Some of these include graphics work, such as labelling. Many narrow web flexo presses also offer an optional screen printing unit, while flatbed machines are often used for in-mold labels. Another use is for graphic overlays for control panels. These typically use PVC, Polycarbonate or Polyester. The graphic is usually printed on the underside to protect the inks though it’s possible to add braille characters on the top. Other typical applications include home decor such as mirrors and shower doors, as well as producing printed circuit boards and solar panels.

Screen printing machines

There are far too many screen printing machines available to list them all here. So we’ve picked out a handful of manufacturers to illustrate the range of different types of machines on offer.

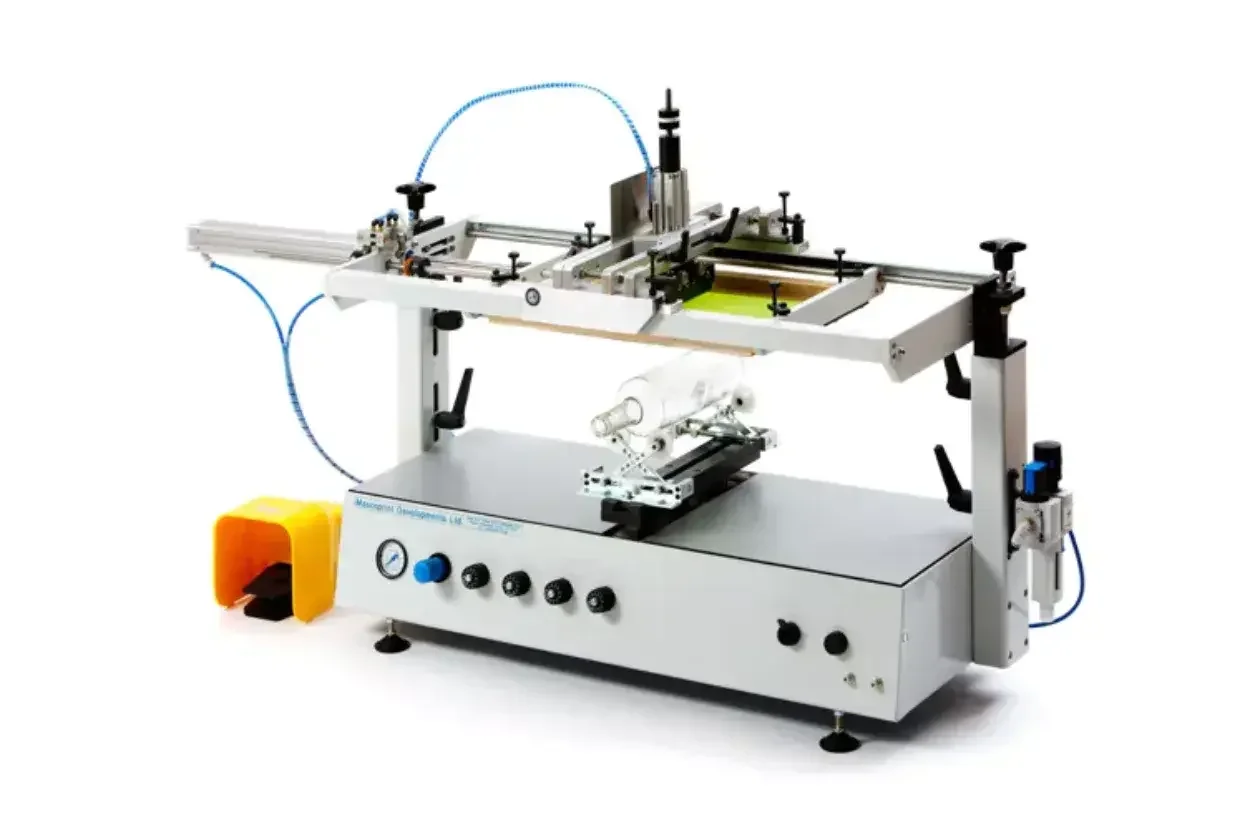

The British company MascoPrint, which is based in Hertfordshire, makes the CP12 bench-top semi-automatic screen printer that’s designed for printing to cylindrical objects. It uses interchangeable jigs to hold the objects in place which allows it to handle a huge range of products, including smaller items like pens and thermometers as well as plastic bottles and alloy cans up to fire extinguishers. Mascoprint will also make customised jigs for specific purposes, such as pipes and tubings and has had considerable success in automotive, medical and other industrial areas. It has a single screen printing station and can produce prints up to 254mm in length and 203mm wide. It runs off air pressure and is operated by a foot control. There is an option for handling flat objects but it’s not really designed for that type of work.

GTO makes several compact industrial screen printers, starting with the GTS350, which is a rotary printer that’s been designed as a general purpose screen printer. It can print all around on cylindrical objects up to 90mm in diameter. But it also has a vacuum suction top to hold flat objects that are up to 200mm in height securely in place, and an optional tool for printing to t-shirts, with a maximum flat print area of 90 x 200mm. It’s suitable for jobs requiring one or two colours and can run at up to 800 cycles per hour. There is a larger version, the GTS 550, that will take cylinders up to 170mm in diameter and print on flat areas up to 520 x 350mm. There’s also a flatbed only model, the GTO 570, which has a printing area of 650 x 500mm.

Kippax, which is based in Yorkshire, UK, makes a number of different flatbed printers, offering manual, semi and three-quarters automation. The basic model is the manual Hand table with an option to add a constant print pressure control system. It’s a flatbed machine, with a choice of ten different sizes offering a print area up to a maximum of 4267 x 1524mm. It features a ball transfer system for material handling, and is suitable for rigid substrates, including glass. It’s typically aimed at the graphics and industrial markets.

The top of the range is the 2000TOUV series, which has a three quarter automatic clamshell design with a gripper take-off system. The screens are front loaded and there’s an optional UV drying system available. There’s a choice of different sizes, with a maximum print area up to 2510 x 1270mm. It features adjustable registration and the squeegee speed and stroke length can be programmed via a HMI screen. The settings can all be saved and recalled when needed. It’s suitable for the industrial, packaging and graphics markets.

Thieme introduced this Vision 3000 AutoLoading screen printing machine earlier this year.

Thieme makes a range of different screen printing machines for industrial uses that can be customised for specific requirements. This includes the Thieme 3000, which has a flatbed design for materials up to 50mm in thickness, and with a maximum print size of 1550 x 2100mm. Its suitable for applications such as printed electronics, solar panels and membrane switches.

Earlier this year Thieme introduced the 3000 Vision AL, which has an automatic loader. As the name implies, it comes with a camera system to ensure the screens and substrates are properly aligned.

The top of the range is the Thieme 5000 MC, a fully automated modular system that can take up to six colours. It’s suitable for flexible materials and packaging.

All this goes to show that although we mostly hear about digital technology, typically inkjet, replacing conventional methods, there’s still plenty of need for screen printing for general manufacturing purposes and this will continue to be the case for many years to come.

To discover the latest content that covers a wide range of sectors including screen printing and personalisation sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.