The apparel industry is being revolutionised by robotic automation and digital adhesives. Companies like CreateMe are replacing traditional sewing with adhesive-based assembly, which is faster and less reliant on skilled labour. This new technology enables localised, on-demand manufacturing, significantly reducing the industry’s environmental impact and fostering a more sustainable future.

For decades, the apparel industry has been built on a complex, global supply chain powered by human hands. The hum of the sewing machine is the quintessential soundtrack to fashion production. Yet, this traditional model is straining under the weight of modern demands: the need for speed, sustainability, and skilled labour. As the industry grapples with a significant skills gap, high staff turnover, and the environmental cost of overproduction, a new question emerges: what if we could build clothes without a single stitch?

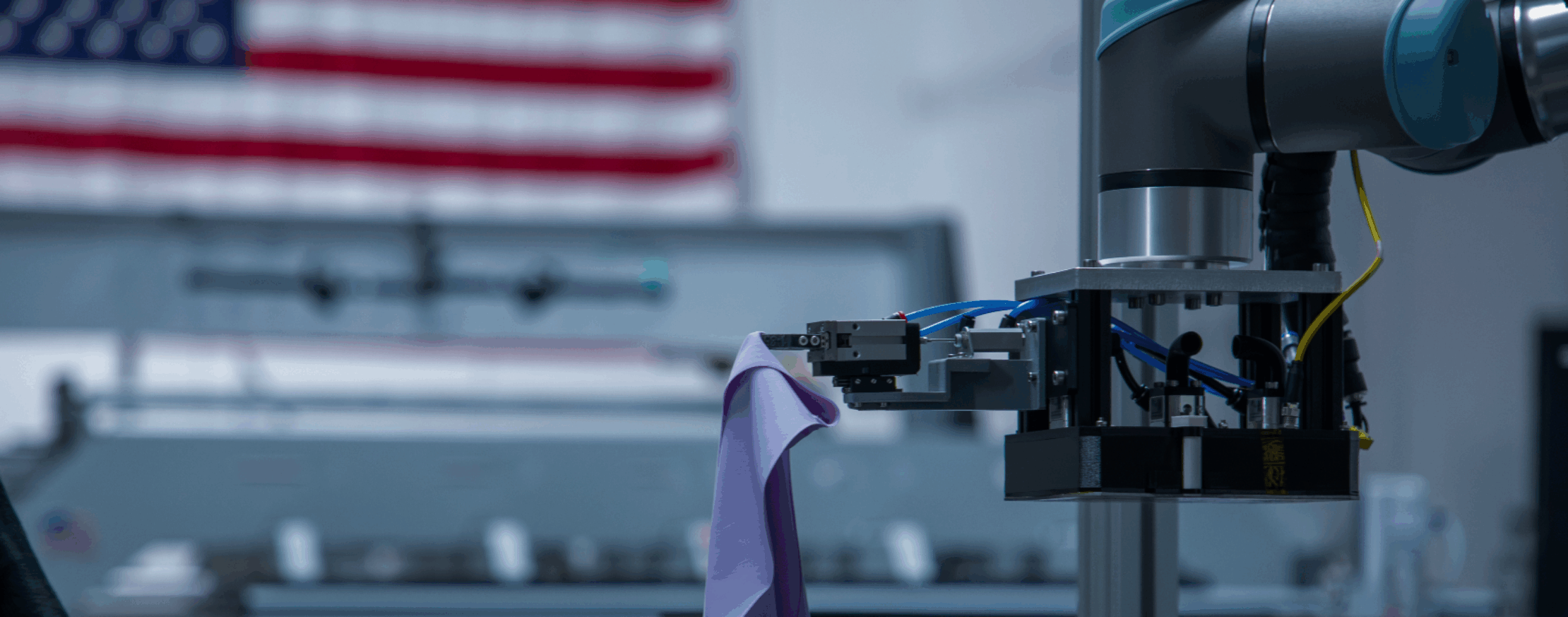

This isn’t a futuristic fantasy. It’s the reality being engineered by companies like CreateMe, a US-based technology firm pioneering the automation of apparel assembly. By replacing thread with digital adhesives and sewing machines with robotic arms, they are not just optimising a process; they are fundamentally redefining how garments are made. We spoke with Cam Myers, the Founder and CEO of CreateMe, to understand the technology that could finally bring apparel manufacturing into the age of automation. Listen to the podcast here.

The Adhesive Advantage: Moving Beyond the Needle and Thread

The core challenge of automating apparel production has always been the complexity of sewing. “Sewing requires an incredible amount of dexterity and skill,” Myers explained. This reliance on highly skilled labour creates bottlenecks, especially in regions like the US where such expertise is scarce. The training period for a skilled sewer can be lengthy, often around 15 days, leading to significant challenges in recruitment and retention.

CreateMe’s solution is to sidestep sewing entirely. “We focus on automating the assembly of apparel using adhesive instead of sewing,” Myers stated. This shift is transformative. By using adhesives, the process becomes a static assembly, making it far more suitable for robotic automation. The result is a digitally driven system that requires significantly less manual skill. According to Myers, new workers can be trained on their adhesive-based system in just one to three days.

This is more than an efficiency gain; it’s a paradigm shift. The process runs 10-20 times faster than traditional sewing and is digitally controlled, much like modern printing. This allows for unparalleled flexibility, making on-demand manufacturing a viable reality.

The Technology: Robots, Dynamic Tooling, and Smart Adhesives

So, how does it work? CreateMe’s factory isn’t filled with sewing machines but with a sophisticated linear conveyor platform system. Robotic arms perform specific tasks with precision, guided by software that can adapt on the fly. “The system is designed to be flexible and can handle high mix and high flow production,” Myers noted.

A key innovation is the use of dynamic tooling. Instead of requiring different physical jigs for every garment size, their system can adjust automatically. This dramatically reduces tooling complexity and the time needed to switch between production runs, simplifying the entire manufacturing process.

The “glue” holding this all together is, quite literally, the adhesive. CreateMe uses commercially available adhesives but has also pushed the boundaries by developing a new, proprietary adhesive in partnership with the University of Warwick. This innovation is critical not just for performance but also for sustainability.

Weaving Sustainability into the Production Line

The apparel industry’s environmental impact is a pressing concern, from carbon emissions in global shipping to the mountains of unsold clothing destined for landfill. CreateMe’s automated, localised model addresses these issues head-on.

“Our adhesive can be de-laminated using heat, making it much easier to recycle garments,” Myers explained. Traditional clothing is notoriously difficult to recycle because stitched seams and mixed materials must be painstakingly separated. CreateMe’s technology simplifies this disassembly, allowing for cleaner waste streams, much like how adhesives are used to deconstruct e-waste. This process avoids the toxic chemicals and high energy consumption often required for deconstruction.

Furthermore, by enabling localised production, brands can manufacture closer to the consumer. This not only slashes the carbon footprint associated with shipping but also allows for a more responsive supply chain, reducing the rampant overproduction that leads to liquidation rates of 30-40%.

The Commercial Reality and Future Possibilities

CreateMe has already commercialised its technology, starting with the production of women’s underwear at a rate of up to 220 units per hour. The company is now scaling up to tackle more complex garments like T-shirts, proving the versatility of its platform.

While high-end, bespoke couture may always rely on the artisan’s touch, automation is set to unlock new creative avenues for mainstream fashion. “Brands are interested in using our technology for specific design solutions, like minimalist looks and seamless fabric layering,” said Myers. The precision of robotics and the unique properties of adhesives open a new toolkit for designers, allowing for innovations that were previously impractical or impossible with traditional sewing.

A New Blueprint for Apparel Manufacturing

The vision Cam Myers paints is one of a radically different apparel industry. The future he sees is not about replacing offshore manufacturing entirely but creating a more balanced, “matrixed supply chain” that blends onshore, nearshore, and offshore production.

By bringing manufacturing closer to home, brands can respond to trends in real-time, drastically improve their sell-through rates, and operate with a far lighter environmental touch. CreateMe’s approach aligns perfectly with the macro trend towards distributed, on-demand production, offering a blueprint for a more agile, efficient, and sustainable future. The journey to automate one of the world’s oldest industries is ambitious, but the potential rewards—for businesses, consumers, and the planet—are immense.

The future of fashion is indeed being bonded, one automated stitch at a time.