Sonja Angerer describes the process of how customers send files to printers for output.

The design is digitally created on a computer and becomes tangible when printed out.

To understand the process, there is a workflow from file to ink droplet:

- How do we get from a design to printable data?

- What happens in a Raster Image Processor (RIP)?

- What factors determine the quality of digital printing?

File delivery as PDF/X is standard today.

It all starts with the design. For decades, designs have been created on the computer or scanned from analogue templates. There are 2 main design file types, vector, and pixel. Vector graphics, created in Adobe Illustrator, Corel Draw or Autocad, are scalable to any size, as objects are described by mathematical formulas. Vector files allow printing in high quality even when the file is large.

In contrast, raster data consists of pixels, each with a specified size and colour. This means that if a file is scaled up, the software duplicates existing pixels and then attempts to optimize the new image by using algorithms. Today, there are options such as “Resize images” in Adobe Photoshop, resizer software such as Luminar Upscale may achieve even better results.

For optimal digital printing results in short viewing distance at least a 150 ppi resolution of the data in its actual output size is highly recommended, resulting in a minimum of 2.480 x 3.508-pixel file for a high quality A4 print. For prints typically viewed from some distance, for example, Mega Posters, a much lower resolution will be sufficient.

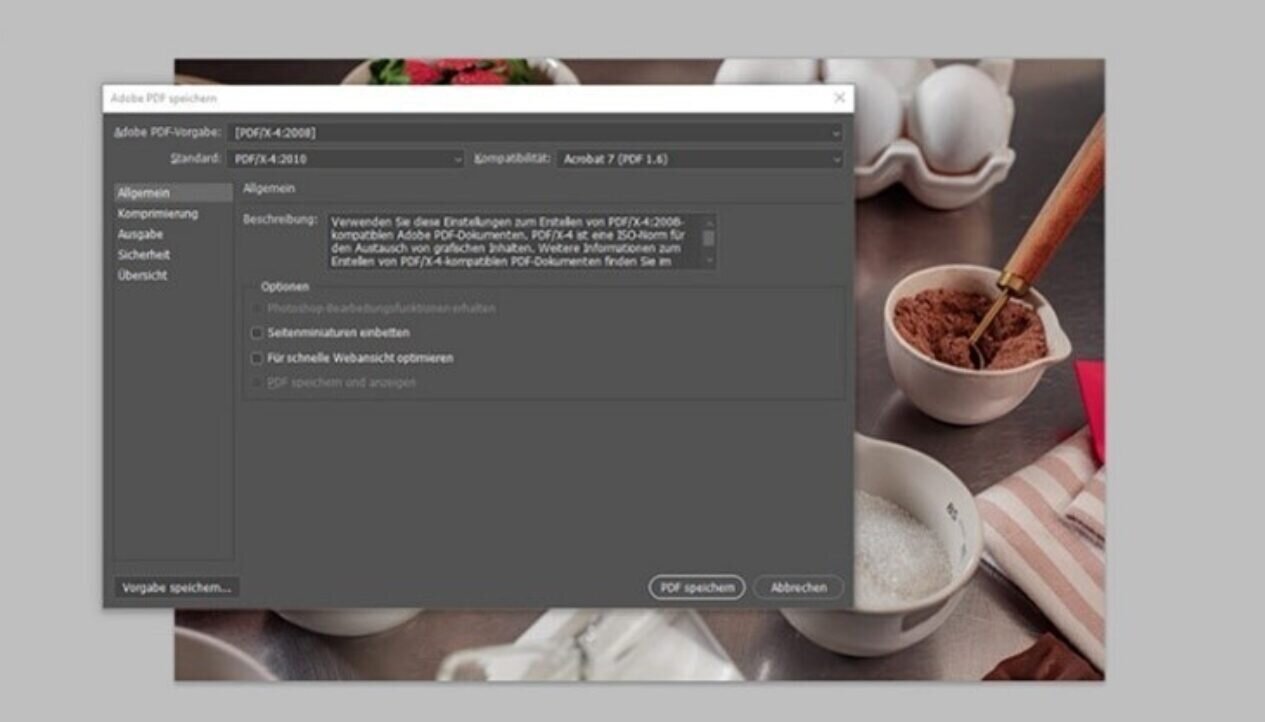

For printing, data is rarely sent to a printer as a native file format but is bundled up into a PDF. The file format was developed by Adobe Systems and may contain text, graphics, images, hyperlinks, forms and sometimes even audio and video files. Today, most printers ask for PDF/X-3, as pro software for layout or design allows for direct PDF/X export (e.g. Photoshop –> file –> save as –> Photoshop PDF).

A RIP will affect output, which is why the brand of the RIP is taken into account in when writing ICC profiles.

From PDF to ripped file

A PDF is expected to uniformly display the elements of a page regardless of the device and operating system. However, this only applies to screens. For any PDF output on an inkjet printer, many coloured ink droplets need to be correctly placed for each element on the PDF.

When ripping, the inks available in the inkjet printer must be considered. An inkjet printer might feature only 4 process colours just like standard offset printing. But some Fine Art photo printers also use up to 12 ink configurations. In offset printing, the raster angles where colours are to be printed on top of each other are clearly specified in DIN 16 547. There are not any technical restrictions in inkjet printing as ink droplets in many sizes can be placed where the head passes over. As a result, different rasters are available for users to choose from, affecting image quality.

The RIP considers colour management information provided by profiles, making sure output on pre-specified layers is exactly as seen on the calibrated monitor (soft-proof) or a test print (proof).

However, most RIPs, whether directly from the printer manufacturer or universal RIPs, can do even more. Customer files get automatically placed into hot folders, where they will be printed as soon as the selected machine is ready. A RIP will position recurring motifs on the print medium efficiently to save on substrate (nesting). In addition, output that is too large and needs to be printed in one piece will be automatically tiled to ensure parts fit for easy reassembly. A ripped file will also contain controls for print heads, head speed, media heating or feed.

The RIP is key

Depending on the printer, ink configuration and substrate, output of the very same graphic file will be quite different. It is much less common to also consider a RIP´s influence on print quality. This is why ICC profiles often also specify the RIP, as between brands, small but significant differences between colours and rasters are possible. For high quality printing, it is important to be mindful that without a well-created file, the ink droplets will not be placed perfectly.