In the face of intensifying climate change, businesses must integrate climate and energy strategies into their operations. This involves prioritizing net-zero initiatives, improving energy efficiency through low-cost changes and investments, and considering the entire value chain. Additionally, companies should adapt to climate impacts like heatwaves and storms to ensure business continuity.

Over the three years since the last time I wrote about this, the impacts of climate change have been biting even harder. Heatwaves are including more days of high humidity along with high temperatures, making it much harder for human beings to cope with them. In June and July this year, a heatwave killed 2300 people in London and 11 European cities alone. Infrastructure was affected globally; forest fires are breaking out in the most unlikely places; storms and flooding have been causing chaos.

If you don’t already include climate impact in your business continuity planning, it’s not too late to start, along with managing energy.

Energy management strategy

Net zero is now a commonly used term, but still not universally understood. It means that the overall global greenhouse gas (GHG) emissions are balanced by their removal. The global element is important: in some places more will need to be removed than emitted to balance out areas where more are emitted than can be removed. Removal can be nature- or technology-based but must be actual removal. To get there, businesses as well as other institutions, need to be involved, and emissions must be reduced.

Energy efficiency ties in with our need to reduce energy bills, and even if you are not planning to take a formal approach to Net Zero, the principles are helpful to understand and use.

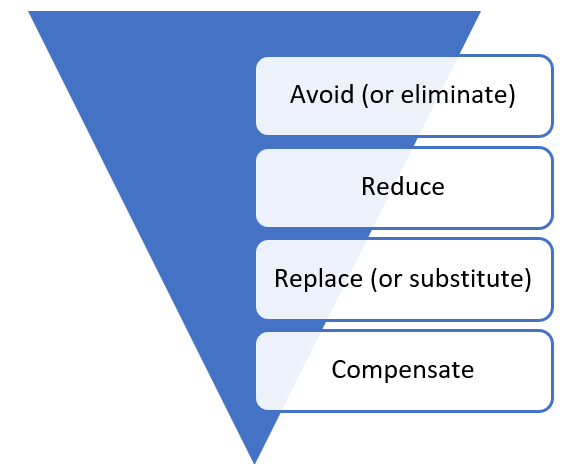

Guidance from both environmental and government bodies, with some variations in detail, is usually based on the same hierarchy:

Following the Net Zero path doesn’t just involve what you do directly but encompasses your entire value chain; for most businesses what are called ‘Scope 3 emissions’ – those from your value chain – are significantly higher than Scopes 1 and 2 (direct emissions, such as those from burning fuel, and emissions from purchased energy). Your activity can therefore be included in the Net Zero plans of your customers or suppliers, and you should consider theirs within your own.

Ways to avoid emissions mainly come from top level strategy and investment decisions. Good opportunities could arise should you be moving premises, considering changes to your business – perhaps moving towards goods and services with lower GHG emissions than you are currently offering. or purchasing new equipment. Investment decisions would include a wide range, from what you do on-site to where you invest for your company pension plans.

Implementing energy efficiency schemes directly reduces energy bills. Behaviour-change programmes to encourage staff to turn off lights, computers, monitors when away from their desks, air conditioning or heating in empty meeting rooms, compressors and any other energy-using equipment left on standby are often overlooked but can be very effective. Low-cost options to supplement this include draught exclusion to eliminate office cold spots and planned maintenance of energy-using equipment, particularly compressors, boilers and air conditioning. Automated controls reduce wasted energy, and the principle can be expanded to full-scale building management systems. Video conferencing to replace physical travel reduces not just fuel costs or fares but also wear and tear on vehicles and any parking costs and congestion charges. Other energy efficiency projects, more costly but usually with fast payback times, include upgrading lighting if you haven’t already done so and improving building insulation: this reduces both heat loss in winter and overheating in summer.

To plan your programme, gather data to track energy use and look to see how it ties in with building occupancy, productivity and external temperatures – that will indicate where savings can best be made. Thermal imaging (cameras can be hired) can identify where heat is lost in winter.

Adding renewable technology such as photovoltaic panels sits at the next level down of the hierarchy, as the best outcomes are achieved if you’ve already reduced energy consumption. So does switching to purchasing electricity from a renewable source.

Some substitutions may only indirectly reduce emissions, so are hard to measure and may not reduce costs. Using materials that generate lower GHG emissions during their life cycle, whether in their own harvesting or manufacturing processes, in how you work with them or at end of life can make quite a difference – but you do need enough information to be able to tell. For anything of this nature, although there may not be a direct cost benefit there may be competitive advantage, as you can reduce the carbon footprint of your products, thus helping your customers reduce theirs.

Compensating or offsetting comes last, both financially and environmentally. Not only is it an additional cost to your business, but it rarely can facilitate the deep cuts that are needed urgently. Offsets currently have a place but are not a substitute for direct reduction; they supplement it.

Coping with climate change impacts

Climate change impacts to consider are effects on your physical assets, such as buildings and plant; effects on your operations, including staff; and emergencies such as storms, flooding and heatwaves.

Adapting buildings may be outside of your control if in a leased site, but even looking at lower cost measures where possible, such as adding external shading to reduce internal heat build-up and any flood-proofing measures available to you, will help.

For operations, keep a check on weather reports to find the hottest times of day in your location and track internal temperatures. If heat and humidity are affecting operations, changing production schedules to cooler times of the day during heatwaves may help, and it may also help staff. Avoiding travel during the hotter times of day is also better for staff wellbeing, if possible, or working at home for certain roles during such periods.

Include risks from floods, storms and forest fires in your risk assessments, considering not only protecting your site, but how they could affect staff travel and health, transport from key suppliers or to key customers. Include indirect consequences, such as potential power outages.