Proofing and Approval Cycles - A practical guide

Paul Sherfield gives us practical advice on how to best manage your proofing and approval cycles

“It did not look like that on my screen!”

“I did not know I had to check it all again”

“My boss does not understand these things”

“You have used the wrong file!”

“What am I checking for?”

If any or all of these comments from customers are familiar, please read on.

Do you have a documented proof approval process?

These strange times will give us all time to consider all our working methods, systems and practises. Have they been suitable for your product mix and your client needs? Will they still be ‘best practise’ when this current crisis is over, and we all return to normal we may find difficult to recognise?

An area that your production and sales teams should make time to consider is proofing and its associated approval cycle. It would also be useful to talk to your customers and get their views on your system in this area.

For what purpose is a proof intended and what areas should be checked by the customer? If this is not clearly communicated by the printer so, therefore, can be misunderstood by the customer who is unaware of what is expected of them. Are your proofing systems and approval cycles suitable for your market and products, and are they understood by your customers.

Your proofing and approval cycle should be suitable for your market, customers and product. Many product and print market areas, such as online web to print, will use soft proofing, often for content only. Other markets such as packaging, labels and high-end commercial printing may need many iterations of colour and content proofing and approval.

So, your solutions and systems need much thought and consideration to ensure they match your customers and market needs.

This area can cause confusion, errors and even reworking and reprints, and the financial outcomes could be in dispute. Not the way to create good customer relations!

So, are you sure your proof and approval process does not contribute to the above issues?

Let’s look at what proofs are used for, in this case covering both soft, on-screen proofing and hard physical proofing; the inkjet and on-press proofs using the production press.

- Colour approval. The proofs, both hard and soft in this area are often called ‘contract proofs’ as they are deemed as a colour master that the printed product must match. Some areas to consider first:

- Are your hard colour contract proofs verified to the correct colour workflow? Is there an ISO 12647-7 validation ‘sticker’ printed or attached to each proof giving this information to the customer?

- Do you give the customer instructions on how to view this proof using the correct D50 based lighting conditions or their alternative such as TL84 for instore?

- How do you ensure that colour contact soft proofs, are viewed by your customer on wide gamut, profiled, colour accurate monitors with the correct colour management settings?

- Do you send a cover page with these soft proofs giving details on how to view and approve these files, often PDF’s?

- Do your customers have the correct software for viewing and commenting on PDF proofs?

- Will the above be understood if these proofs are seen or viewed by others within your customer’s organisation?

- Content approval, both soft and hard proofs:

- Do your customers understand that these proofs are for content only, not for accurate colour approvals?

- Will this be understood if these proofs are seen or viewed by others within your customer’s organisation?

- Do your customers have the correct software for viewing and commenting on PDF proofs?

- Revised proofs

- Are they for colour, content or both?

- Should only the corrected areas be checked or all elements? This will depend on the extent of the correction and who carried them out, and the requirements should be made clear.

- Does an attached cover page document this approval process and the stage it has reached?

The approval process

Let’s now assume that the technical areas of proofs, both hard and soft, have been addressed and corrected, and that:

- All physical colour contract proofs have a validation label showing compliance to ISO 12647-7 and the colour managed workflow and profiles used and advice is given on viewing conditions.

- The proof approval system in place.

- Soft proofs are clearly marked for purpose, colour including the monitor colour caveats, or content only.

- Revised proofs have instructions on what the customer is required to check.

So, what is left?

Managing where you and your customer are within the approval process:

- Is it the first, second, third etc round of proofs? How is this recorded and managed, on a proof slip, in the job bag?

- Who is carrying out the corrections, you, or is your customer supplying new corrected files?

- If so what type of reproof do they require, does the approval process start again?

- Older versions of customer files need to be managed to ensure there is no confusion, so version control is needed.

- Final approval from the customer must be clear and documented

- If this final approval is subject to you carrying out further corrections, should you consider a further proof submission, despite your customer’s instruction

- How are the costs of authors corrections calculated and recorded?

- Are customers advised of these costs before they are actioned?

- Are customers asked to approve correction costs in writing?

Remember that old saying: “There is always time for a reprint!”.

Some actions to consider:

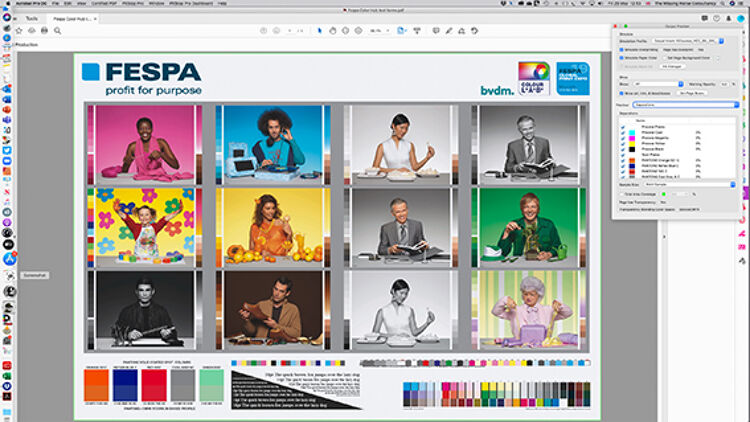

Affix D50 sticker to physical contract colour proofs to indicate incorrect viewing conditions, these can be reused. The stickers, when viewed under incorrect lighting show strips of colour as seen in the image below. When viewed under the correct D50 lights, the strips should be barely visible.

https://www.ugra.ch/en/product/ugra-light-indicator-strip-d50/

Use approval stickers/interactive PDF/word docs s for approval/comments/ corrections and further actions/re-proofs etc

This interactive form is downloadable for you to customise and alter to your needs. It could be included as a cover page for PDF proofs, or as a paper form for physical proofs. However, an online proof approval system would be much more transparent and traceable, even for physical proofs.

Many free PDF viewers will not display a complex graphic arts PDF correctly for colour or content! Acrobat Professional is the ‘gold standard’. So, always advise customers on the viewing issues with other PDF software.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Smart factories and customisation technology explored at Personalise Make Wear 2024

FESPA's Textile Ambassador, Debbie McKeegan speaks to industry specialists at Personalise Make Wear at Personalisation Experience and Sportswear Pro 2024 held in Amsterdam. Each day of the exhibitions Debbie hosted a fire-side chat with these specialists to discuss various industry topics. During this Fire-side chat with Antigro, Caldera, Print Logistics, Inkcups and Kornit Digital they discuss the role of digital technologies in personalisation, reshaping the supply chain, the future of manufacturing and more.

The pros and cons of Digital Signage and Printed Signage

Sonja Angerer discusses the pros and cons of both digital signage and printed signage. Current developments such as artificial intelligence and spatial computing are changing the situation once again. How will this shift affect printers?

How to create an efficient smart factory

Debbie McKeegan speaks to industry specialists at Personalise Make Wear in Amsterdam about smart factories and customisation technology. Debbie speaks to Antigro, Caldera, Print Logistic, Inkcups and Kornit Digitial.

Standard lighting conditions for wide format printers and their many markets

Paul Sherfield shares the various standard conditions that are required for wide format printers as colours can appear differently dependent on the differing types of lighting and environments.