Debbie McKeegan speaks to Future Fashion the largest digital textile printing company in Pakistan who utilises high speed industrial digial textile printing machines. There is a large home market in Pakistan which absorbs many 100’s of millions of metres of printed textiles for its own population, particularly fashion.

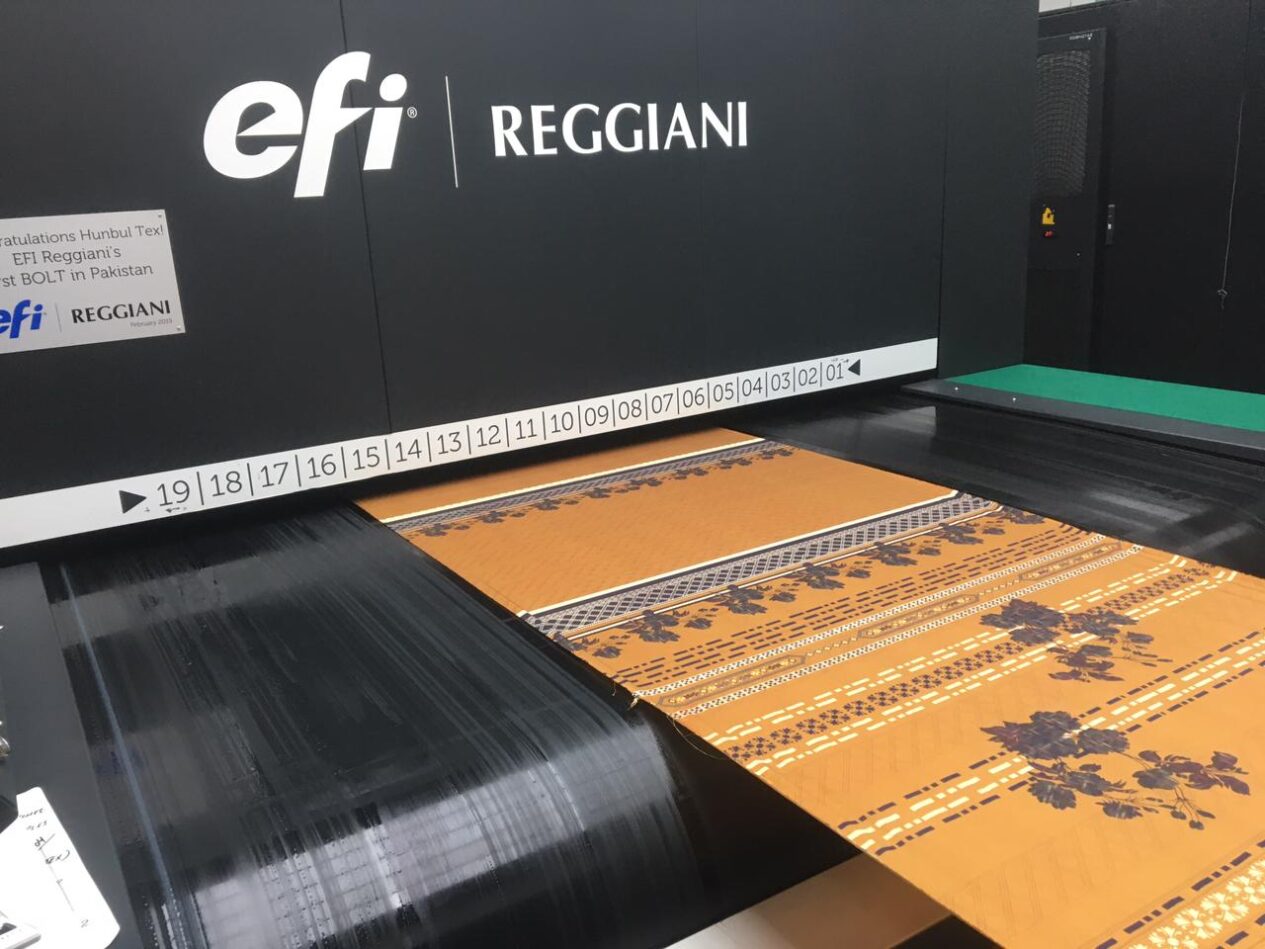

Future Fashion is the largest digital textile printing company in Pakistan. Founded in 2019, The Company is equipped with the latest single pass digital printing machinery, including the EFI Reggiani (BOLT). In fact, this machine, purchased at ITMA in 2019, was the first installation for this ground-breaking technology and marks a moment in time for the adoption and acceleration of industrial scale textile production machinery in South Asia.

The company also utilises another 6 digital scanning printers, 4 by MSItaly and 2 from AtexCO China. Printed production is supported for Pre and Post finishing by state-of-the art European technology.

It often a false assumption of the West that the majority of the printed meterage manufactured in Southern Asia is destined for our shores. That’s not always the case. Pakistan represents a huge home market and one that absorbs many 100’s of millions of metres of printed textiles for its own population, particularly fashion. In fact, this case study reflects just that – on shore production. A major investment in on-demand digital technology for the markets within Asia. That’s not to say that the volumes of South Asian print destined and exported for the West are insignificant, that would be incorrect, but for Future Fashion (Pvt) Ltd currently Asia is the main market for their digitally printed textiles.

Planning for the new venture, Future Fashion, began at the launch of the EFI Reggiani (BOLT) in 2019. A single-pass machine from our trusted partner EFI. Hunbultex was the first company in the world to buy the BOLT.

In this interview we talked with Rana Muhammad Imran Afzal, General Manager of Future Fashion. With a background in traditional, analogue technology and years of experience with digital machinery throughout his career, he took the role of GM with overall responsibility for printed production and was instrumental in the projects execution. Imran explained “Our parent company Hunbultex, is the largest digital production company in Pakistan with 22 scanning printers, most of them from EFI Reggiani”.

“Planning for the new venture, Future Fashion, began at the launch of the EFI Reggiani (BOLT) in 2019. A single-pass machine from our trusted partner EFI. Hunbultex was the first company in the world to buy the BOLT. The new company FF is equipped with one BLOT and 6 Scanning printing machines (MSItaly and AtexCo China).”

“The project was signed off in mid 2019 and took approximately 9 months to complete the build and installation of the machinery for pre and post finishing and digital textile printing. COVID caused a number of delays, but overall, this was an impressive achievement is such a small timescale”.

Future Fashion now produced 25 to 30 million linear metres of digitally printed textiles in one calendar year with their primary market being Pakistan’s fashion industry. Imran explained further “We are providing commercial printing services to top local brands which also have stores abroad as well. We are also providing printing services to international sourcing offices who are exporting their goods to the USA and EU.”

Future Fashion only offers digital production, with no analogue/rotary technology. Imran commented “On the basis of my experience working in conventional and digital textile printing companies, I believe there is a significant split in the benefits for both methods of print. Digital productions are more precise, no limits on colours or design repeats. No wastage or issues with design registration. Digital production is labour efficient, needs less power and other utilities. Importantly it is sustainable and environmentally efficient in its use of valuable resources, such as water. On the other hand – Rotary production has a better colour yield, especially for solid grounds and blotches.”

Future Fashion now produced 25 to 30 million linear metres of digitally printed textiles in one calendar year with their primary market being Pakistan’s fashion industry.

“The future definitely belongs to digital, with the successful introduction of single pass machines – the quality issue has been resolved. In my opinion, when digital pigment inks are kinder to ink heads and are cost effective, then huge quantities of blended fabrics for Home Textiles will be shifted to the digital printing system, which I believe will be a revolution.”

We asked Imran why now was the right time to switch to digital production in Pakistan?

“As Pakistan is one of the top 5 countries in the world for cotton production, mainly exporting to global markets, it also has a huge local population of 250 million. This was the right time for Hunbultex to invest and in our digital production facilities, our investments in modern technology continue to secure the future of the countries printed Textile Industry. Many companies in Pakistan are following these steps and growing”.

How have your customer’s needs changed? What is the typical lead time for printed fabric in 2022? “Interesting question – The needs of our customers have changed dramatically. Their expectations are high. Thanks to our investment in the BOLT single pass technology, we have been able to reduce MOQ’s and offer our customers a variety of designs. Lead times vary from company to company, Future Fashion has the capacity to print 100,000m of Cotton and Viscose fabrics daily and 6500m for Polyester. We offer 15 days delivery worldwide.”

Do you see a greater diversity in the patterns printed, with new designs building total meterage, rather than traditional volume meterage using single pass printing machinery? “Digital printing has diversified the printed patterns immensely. With the single pass machines, MOQ’s have changed. The same quantities can be printed with more designs, and we can also mix SKU’s in the print run to include panel prints. In turn this has created a huge demand for designs, which has created a lot of jobs for creative designers and pre-press professionals”.

With ready access to on-demand printing we asked Imran if the fashion industry is serious about sustainable manufacturing, and will they accept that change requires a collaboration on margins between vendors/suppliers?

Future Fashion have installed the latest technology and offer the market a sustainable printing solution that’s kind to the environment and their local eco-system, with the capacity to print 100,000m of Cotton and Viscose fabrics daily and 6500m for Polyester using digital printing technology, they now offer 15 days delivery worldwide.

“They have to be serious and in fact they are, because I believe the biggest benefiters of all aspects of digitization, printing and processing – are the Fashion Industry. The future is sustainability, with unpredictable economic and environmental issues around the world – only sustainable manufacturers will survive. Fashion brands must also work on margins, and they must reset priorities. Digital printing has given new opportunities to small businesses allowing them to grow, customisation is in my view a big threat to brands.”

Imran added: “Future Fashion itself is based on Sustainability. The vision behind the immergence of Future Fashion was to provide high quality textile printing and processing services to the brands of Pakistan. The new company will also encourage new business. We have installed the latest technology and offer the market a sustainable solution that’s kind to the environment and our local eco-system.”

Future Fashion has set a new benchmark for all industrial Textile printers worldwide. This futuristic vision and their substantial investment in digital technology (during the hard times of COVID) has ensured that they are equipped to succeed. Transforming Pakistan’s textile heritage to meet the needs of new era of sustainable textile production. We look forward to celebrating their continued success.