The print industry is still adapting and changing due to ramifications of COVID-19. However, the climate crisis requires our attention more than ever. While de-carbonising value and delivery chains seems an inconvenience for printers there are ways to help start this process.

In the next 8 years Germany aims to reduce greenhouse gas emissions by at least 55% compared to emissions in 1990. This is only a mid-term goal, as the country pledges to become predominantly carbon-neutral by 2050. Many countries in the European Union have set up similar programmes.

Why Should Printers Start to Take Action Against the Climate Crisis?

As industrial production is considered the second largest source of greenhouse gas, the government are expecting businesses to contribute and take responsibility. Making small changes to a business such as changing company car brand to an electric alternative is not enough to make an substantial change against climate change.

Carbon emissions certification prices are expected to significantly increase within the next few years, as well as energy and industrial waste disposal. As the awareness of the dangers Climate Change poses to humankind increases, customers demand for sustainable solutions are increasing. demand to know what their suppliers do to help fight global warming.

Caption: Products from companies at a ClimatePartner Academy (2018). Image credit: S. Angerer

How to start becoming more climate friendly

There are available standard processes to evaluate sustainability in production, such as the ISO 14001 environmental audit. Unfortunately, a full audit is expensive and the paper-work required can be overwhelming for smaller businesses. There are some local initiatives like Ecoprofit / Ökoprofit that are helpful. Metropolitan areas like Hamburg and Munich have been actively promoting Ecoprofit / Ökoprofit for over 20 years. Fees apply and are dependent on the company size.

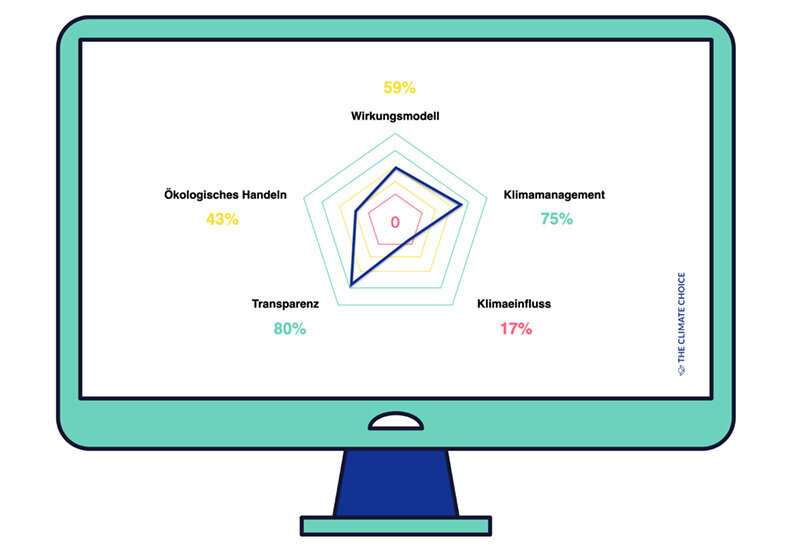

The Climate Choice, a Berlin-based start-up with the goal to “empower every company to become a Climate Champion”, takes a slightly different approach. “We specialise in SMB”, explains Lara Obst, one of the three founders. “Our ‘Climate Readiness Check’ is a unique process where we make good use of our proprietary software. In the standardised 1 hour check we help businesses to identify quick and easy wins, find climate-friendly solutions and ensure that they comply with upcoming climate requirements.” Based on the evaluation, consultants can suggest basic steps for SMBs e. g. to reduce the use of energy on their premises, but also de-carbonize their supply chain when over 85% of all corporate emissions occur.

“We want to make it as easy as possible for companies to change their businesses, so they are more climate friendly and sustainable”, says Obst. Companies that have completed the Climate Readiness Check are added to the Climate Data Platform and receive a Label in gold, silver or bronze based on their climate performance. “Having undergone the check, many businesses can meet existing customer´s requests to provide data about their processes but can also attract new clients by focusing on sustainability.” A basic Climate Choice ‘Climate Readiness Check’ for a business with up to 50 employees costs approximately 1,000 Euros.

For the last 2 years, Climate Choice has organised the Climate Transformation Summit online conference, with the latest conference occurring in the summer of 2021. The conference attracted approximately 600 high-profile participants.

Caption: The Climate Choice uses its own software for the ‘Climate Readiness Check’. Image credit: The Climate Choice

Avoid or Compensate?

Avoiding and reducing carbon emissions is a main focus of The Climate Choice. ClimatePartner is another consultancy specialising in helping businesses transform and become more sustainable, carbon offset is an important part of the mix. The company also offers regional projects in the DACH region where their customers can invest into reducing carbon emissions.

With some focus on the printing industry, ClimatePartner had been holding regular ClimatePartner Academy meetings in German-speaking cities where clients and interested parties met to learn about best practices and the latest developments. Due to COVD-19, the Academy meeting was moved online and lasted 90 minutes. The meeting focused on a single topic, “Deep Dives” which was free of charge for pre-registered participants.

Do small printers have to become more climate friendly?

While some people believe that being environmentally responsible is only necessary for larger businesses, the latest natural disasters have contributed to an ongoing climate issue. This has risen awareness that all businesses regardless of their size must do their best to help save our ecosystems from collapsing.

With their larger impact, companies, including printers have to be more reactive than end consumers to ensure that they save their business and the environment. Today, there are several affordable options that can help businesses of all sizes start this process.