The Fashion industry is in flux, but for the manufacturing community, production technology and CAD/CAM has been front of mind for many years. Driving the digitization of design and sewn manufacturing for over 40 years, is Ram Sareen, chairman and founder of Tukatech, based in LA.

The Fashion industry is in flux, but for the manufacturing community, production technology and CAD/CAM has been front of mind for many years. Driving the digitization of design and sewn manufacturing for over 40 years, is Ram Sareen, chairman and founder of Tukatech, based in LA.

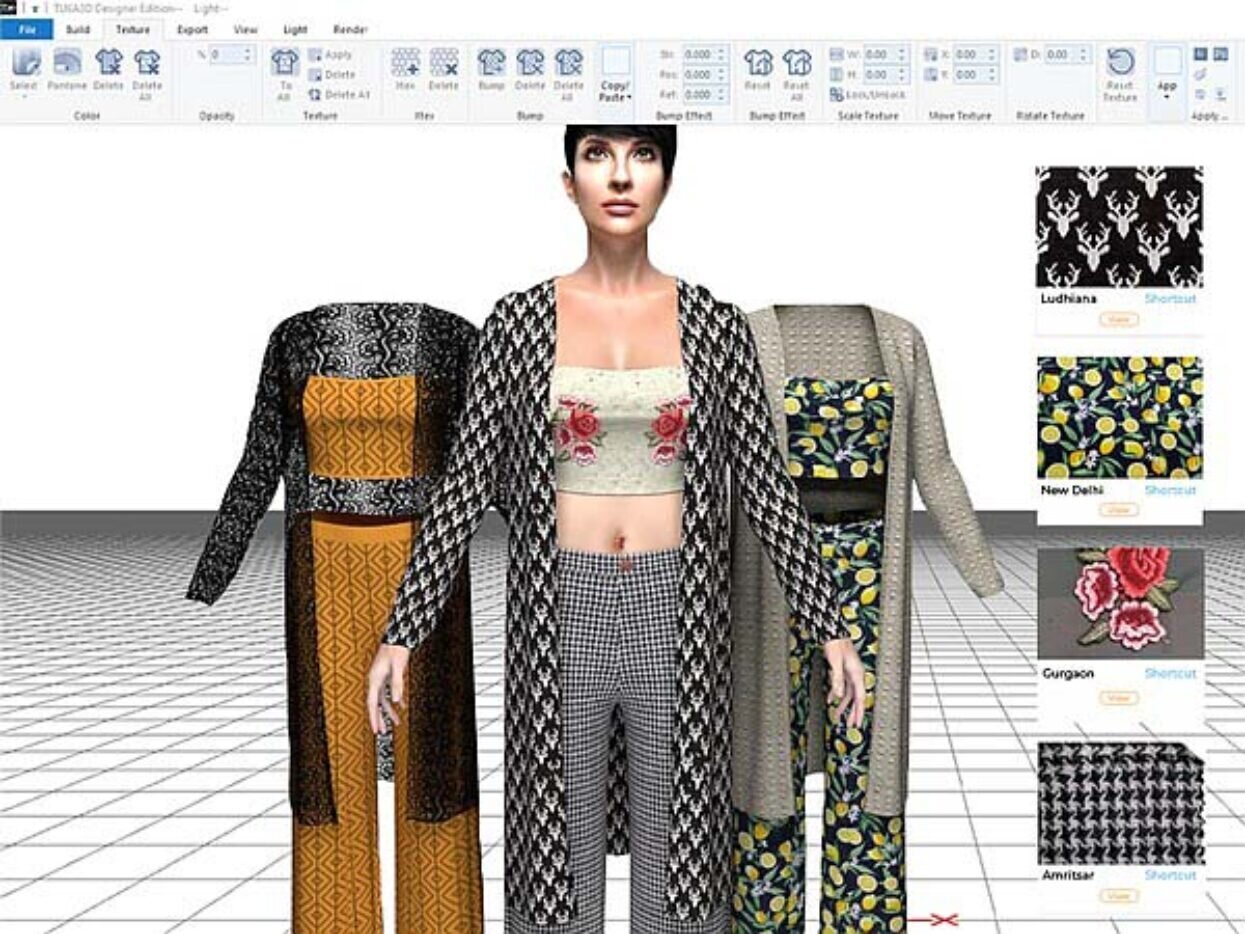

Ram has served the garment industry for many decades, with an extensive knowledge and manufacturing history characterized by one word – disruptive. His vision and philosophy are ingrained in Tukatech, the fashion technology solutions company that Ram Sareen founded in 1995. Tukatech is credited with successfully bringing digital pattern making to dozens of countries and they are an innovative leader in virtual sample making, design and fit with real time motion simulation.

They were the first to develop and implement on demand manufacturing processes and are renowned for their advanced cutting room solutions. Tukatech’s robust systems are implemented by fashion experts from all corners of the garment industry. Ram kindly agreed to share his insights, wisdom and experience in our recent podcast interview. Listen to the full podcast here:

Ram Sareen, CEO and founder of Tukatech, how did you start out in the apparel industry?

“By default, my family was in the fashion business, although I’m a mechanical engineer, but the dining room conversation on a daily basis growing up, was fashion. I was born and raised in India, hospitality is number one there, you share your food, culture, and your life. So almost on a weekly basis, I would be exposed to designers or buyers coming in from UK or USA. And so, I spent my formative years sitting and listening to visitors. I had no idea of the value of the fashion industry insights that I was getting.

Caption: Tukatech is credited with successfully bringing digital pattern making to dozens of countries and they are an innovative leader in virtual sample making, design and fit with real time motion simulation.They were the first to develop and implement on demand manufacturing processes and are renowned for their advanced cutting room solutions.

My biggest dream (I joke about it) because as soon as I became 16, it became my responsibility to take the visitors to show them the Taj Mahal, an icon in India, a four- hour drive. I had no idea how much knowledge I was absorbing on those journeys, is almost like deja-vu looking back. I began to enjoy the fashion business. I think it’s very challenging, nobody knows the answers, but it’s very creative. It’s worse than a drug – I’ve tried to get out of this twice. I retired when I was 35 years old. Two weeks later, I was back in. I retired in 1994, December, having had a cardiac arrest and I said okay, this time I really did try. Six months later I was back in – fashion is in your DNA? It’s not a motivation from any other sources it’s really enjoyment.”

When did you found Tukatech and what technologies do you provide?

“So, my focus when I started was two-fold. One was technology is here to stay. And we need to get on the technology. Historically, the garment industry was led by artisans, people who were creative, they did things with their hands. The industry was built upon passed down skills: a pattern cutter, or a pattern maker, who may not have gone to school, even high school, but had the skills to create an amazing dress or a garment to fit on a human body, the three-dimensional body, from a two – dimensional patterns to fabric behaviors, how did they know this? This was an apprenticeship program; people learn from one to the other, to the other. There were no formal schools and colleges, even when the CAD systems came out, they all had CAD, for grading and marker making, pure science is pure science, you don’t need human beings for that. I mean, if people had to buy pattern grading, digitizing, and then marker making, plotting, if that was the only thing, they should have bought it for $19.95 – the real challenge was the creativity of the pattern and big companies had failed to implement that. The cost was too high, the learning curve was too steep.

Caption: “So, my objective when I restarted my new life, and I called this my second life, was to only go and teach people how to make patterns on the computer. So, we designed the system as a $10,000 station with hardware software, unlimited training, it removed the barriers..” Commented Ram Sareen

So, my objective when I restarted my new life, and I called this my second life, was to only go and teach people how to make patterns on the computer. So, we designed the system as a $10,000 station with hardware software, unlimited training, it removed the barriers, because in those days, it was about $50,000 to do the same thing with other technology companies. We had to really come up with a business model. How many of these solutions do we have to sell to survive? How do we train the people in the shortest possible time? How do we make sure the person who has never touched the computer can learn quickly? Remember, this is 1995, Windows 95 was my motivator. When I saw that platform, I recognized that Windows was multitasking, multi-processing? I realized that you don’t have to make a user a programmer. So, my designing of the system was designed for dummies. Anyone who’s old enough to remember, there was a thing called Design for Dummies.

That was a motivational tool for me because I had to think the same thing – it is not that people are dumb, it’s just that they don’t have that skill. And why do I have to teach them the skill? I just have to transfer that skill on to the computers. So, I had to come up with that platform. I still remember in 1995 talking with a 55- year-old pattern maker was working a clothing line in India, this 55-year-old who was so afraid to press button, because he thought he was going to delete everything. Making patterns on the system, over and over again, as human beings, we realize, if you touch something, and that becomes easier, you want to do it…and the Tukatech solution began to flourish…

You know, we have a thing called less is more. And in that has to be the focus for any business today. How do I get more from less? It’s a long answer for a small company. But we’ve had 27 years. And we have not deviated from our focus to simplify the process, not just leave it as one button, but continue to make more buttons and more buttons and more buttons. To the extent that today we have what we call automatic pattern making. I can take the CEO of that company in 15 minutes, and make that person, a great pattern maker…”

Over the last 27 years Tukatech’s software solutions have developed to encompass garment design all the way through to automated production, to pattern nesting, pattern marker making, grading and also solutions that then can help people cut fabrics at the other end of the scenario to offer a total 360 manufacturing solution.

Caption: “You know, we have a thing called less is more. And in that has to be the focus for any business today. How do I get more from less? It’s a long answer for a small company. But we’ve had 27 years. And we have not deviated from our focus to simplify the process…” explained Ram Sareen

“Everybody who came with us on the Tukatech journey is still in business, and they are making money, they just wanted to get better. So, they have made an investment in a CAD system, they now also have a plotter and a digitizer.

We were the first company in the world to come up with a totally open system. I said we are going to work with everybody’s language, and I created software that could read everybody’s files. And I could send those to any manufacturer.

We became the darling of all the factories and vendors because it was a problem they needed to solve. We are not very big with designers and brands. But we do control most of the big countries who are exporting countries, 90% of Sri Lanka uses my technology and they all had different technologies 75-80% of Pakistan and 75-80% of India, and Bangladesh have invested in Tukatech software solutions.”

This short summary is only a small account of this enlightening interview. It was an honour to talk with Ram Sareen, his lifelong passion for the fashion industry palpable and his is manufacturing and technical knowledge seemingly infinite.

We went on to discuss:

- What challenges does the Global Fashion Industry face?

- Do you see a switch to smart, local manufacturing – globally? Are smart hubs the future?

- Is the American fashion Industry serious about reshoring? Where are the skills gaps?

- Who carries the risk? Can the fashion industry rationalise margins to support manufacturers?

- How do we tackle garment sizing? Even in an on-demand world poor sizing creates waste?

- Finally – what would be your vision for the future of fashion production? Can we turn the ship towards sustainable manufacturing?