CNC routers: the difference between cutting tables and routers and what is available?

A CNC router can come in handy for sign and display graphics as well as helping wide format printers expand into other industrial markets.

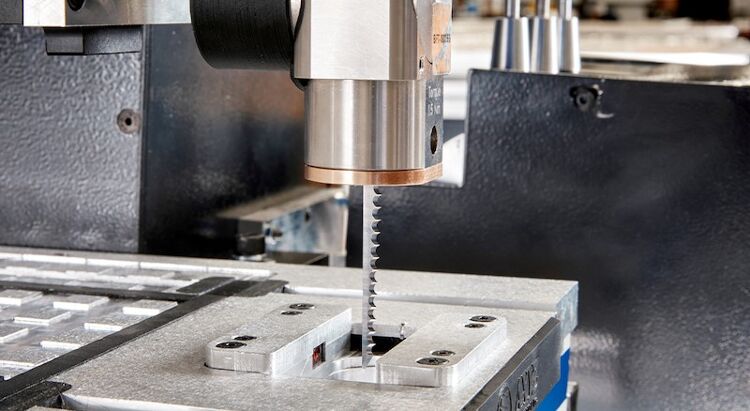

Last month we covered digital cutting tables and this month we’ll look at a more heavy duty alternative, the CNC router, which is better suited to fast cutting of dense materials such as wood, plastics, aluminium composites and soft metals as well as common substrates such as acrylics and foam board. These are all common materials for anyone involved in display graphics and plenty of wide format users also run CNC routers. Many now also include heads for different types of knives so that they could also be used as an alternative to a cutting table. And since these machines are extremely versatile, they can also be used for a number of other applications such as making furniture or components for other manufacturers. As such, they’re a good option for anyone looking to expand their horizons.

Routers themselves have been around for a long time and can be used not just for cutting right through materials but for cutting grooves and other shapes into those substrates. This can be done manually for the occasional job but if you have any kind of volume then its best to look at automation, which is where Computer Numerical Control or CNC routers come into their own.

There are a number of things to consider when choosing a CNC router. Firstly, it will need to have a solid frame to counter any vibration from the cutting. It should also have vacuum pumps that cover the bed to hold the material in place as it’s cut. The table has to be small enough to fit your chosen space but big enough to handle whatever boards you might want to work with in the future. Equally important is the height of the materials and whether or not you are working on 3D items or just cutting flat panels and therefore the amount of clearance the gantry will need.

Another consideration is the drive system that allows the cutting heads to move along the X, Y and Z axis. There are two basic types. Ball screws use a long grooved screw, fastened at each end, with the nut using ball bearings to travel along the screw. They come in different grades with the more expensive being more accurate though these can offer a very high degree of precision. The disadvantage is that the longer the length of the ball screw the greater the risk of introducing inaccuracy into the movement. Consequently this is most likely to be used for the shorter Z axis.

With a rack and pinion system, a rack is bolted to the sides of the machine, while a cog or pinion is attached to the movable gantry, and teeth on the pinion slot into the grooves on the rack. In some cases the rack is straight but its more common to use a variation where the grooves in the rack are angled, called a helical rack, which ensures the pinion has more than one tooth engaged at a time. In general, the helical rack drives are better over longer distances and easier to maintain because they are bolted directly to the frame though it really depends on how any given drive has been specified. Regardless of which type of drive, most vendors have now switched to using servo motors rather than belt drives to power the movement.

Typically, any given board will have a number of different things that need to be cut, or possibly even different jobs that have been ganged together, and which might require different tools. Most CNC machines should have a way of automatically switching between these tools without requiring any manual intervention. This could include a multi-head with two or three heads combined to hold different types of tools, as well as an automatic tool changer allowing further tools to be picked up as needed. It goes without saying that there should also be a good range of tools, including knives as well as routing heads.

In addition, there should be some kind of dust extraction system, which is sometimes offered as an optional extra. Even so, it’s probably a good idea to house the CNC router in a separate room as they tend to be noisy and to produce a lot of dust, even if fitted with an extraction system.

What’s available?

There are quite a number of different CNC routers available, some better suited to sign and display graphics work than others. We’ve picked out some of the most common but this is by no means an exhaustive list.

.jpg?lang=en-GB) Caption: AXYZ introduced this Innovator CNC router last year. Image credit: AXYZ.

Caption: AXYZ introduced this Innovator CNC router last year. Image credit: AXYZ.

Axyz, which is based in Canada, produces several different types of CNC routers split across five main brands covering a range of different industries. These include the Innovator, which was launched at the end of last year as an entry-level model that’s also suitable for sign making. It uses helical rack drives with servo motors. It’s available in two sizes - 1244 x 1346mm and 2438 x 1524mm - both with a gantry clearance of 152mm. It can cut aluminium, plastics and hardwoods and there’s an option to add a tool changer that can hold up to three tools

Axyz also introduced an updated version of its Trident series earlier last year, which has gained greater automation and productivity. It’s designed as a versatile machine that includes a routing spindle with tangential and oscillating knife units. There’s a new knife tool, which oscillates more quickly so it can handle a wider range of media.

The American brand Multicam has developed a broad range of CNC routers, each offering varying levels of features and cutting power to suit different applications. These include the 7000 series, which comes in several sizes offering a working area from 1.5 x 3m up to 2.1 x 4.3m with 203mm clearance on the Z axis. They use a helical rack and pinion drive on the X and Y axis and a ball screw on the Z axis. The base frame is a one-piece welded steel frame with cast iron supports for the gantry. It comes with a 13.3hp spindle but this can be upgraded to a 16hp unit. Amongst the optional extras is an automatic tool changer and a registration camera system as well as a dual head and a tangential knife.

Tekcel, which hails from Australia, makes three series of CNC routers, starting with the compact P2. This has a table measuring 2490 x 1260mm, taking materials up to 110mm in height. It has a 4kW spindle and should be suitable for most sign making jobs. As with all the Tekcel machines, it’s fitted with an automatic tool rack that can hold up to ten tools so that the machine can automatically pick up designated tools for a job, and change tools as necessary.

Tekcel also makes the M-series, which is really aimed at the wood working market. This comes with a 9kW spindle and can hold up to 16 tools. It’s 1800mm wide but with a choice between 2500 and 3660mm long. It has an automated system for loading sheets on - and cut parts off - the bed.

The Enduro series is Tekcel’s answer for heavy duty work loads, also fitted with the 9kW spindle. It’s available in six sizes from 2500 x 1540mm up to 4100 x 2058mm, and with clearance from 140 to 500mm. The automatic tool rack can hold up to 18 tools. All the Tekcel machines uses a ball screw drive with servo motors for all directions.

Mantech Machinery, based in the West Midlands in the UK, makes a number of different CNC routers, including the entry-level Spartan series. This comes in various sizes, starting with the smallest 600 x 900mm bed up to 2x3m. The most basic of these models come with a 2.2kW spindle and use ball screw drives on all axis. However, there’s also a much higher specification version that comes with an automatic tool changer on a 9kW spindle and is fitted with a helical rack and pinion drive on the X and Y movements.

Mantech also makes the top of the range Apollo series, which now also boast automatic tool changing. It uses a 9kW air-cooled spindle with a helical rack drive for the X and Y axis and an enhanced dust extraction unit. The Apollo also comes with a touchscreen control and Mantech’s own M-Tech motion control system plus additional options including a camera system and an oscillating knife unit.

In conclusion, it goes without saying that price is always important but although a standard machine may be cheaper, a decent supplier should be able to tailor a bespoke configuration that might better meet your needs. In addition, these machines last a long time so it’s essential to pick a supplier that you are comfortable with, one that can take care of the servicing, any necessary training, and advise on tooling for new applications.

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The pros and cons of Digital Signage and Printed Signage

Sonja Angerer discusses the pros and cons of both digital signage and printed signage. Current developments such as artificial intelligence and spatial computing are changing the situation once again. How will this shift affect printers?

How to create an efficient smart factory

Debbie McKeegan speaks to industry specialists at Personalise Make Wear in Amsterdam about smart factories and customisation technology. Debbie speaks to Antigro, Caldera, Print Logistic, Inkcups and Kornit Digitial.

Standard lighting conditions for wide format printers and their many markets

Paul Sherfield shares the various standard conditions that are required for wide format printers as colours can appear differently dependent on the differing types of lighting and environments.

_compromised.jpg?width=550)