The main drivers behind the growing number of inkjet textile printers are the garments and furnishings markets but where does that leave soft signage?

There’s no question that there has been a dramatic growth in soft signage in recent years – that is printing display graphics to textile substrates. There are many reasons for this, not least that the graphics are easier to store, transport and assemble, as well as being recyclable. In addition, many people feel that a backlit textile looks much better than a backlit film.

But it’s worth asking just how the soft signage is printed. The obvious method is to use a dye sub printer, either to print to a transfer media or direct to textile. Dye sublimation forces the ink to penetrate deep into the fibres of the fabric, so that the pigments form an inherent bond within the substrate that can survive the washing, long exposure to sunlight and the adverse effects of bad weather. Moreover, the fabric retains its texture, though this isn’t really a concern with most signage.

The ability to survive outdoors for long periods does mean that dye sublimation is more suitable for products such as flags or banners that are likely to be used for several years. But when it comes to short term promotional banners, or for exhibition graphics that are used indoors, many companies are finding that eco-solvent, latex or even UV, is quite acceptable.

So, not surprisingly, many print companies are using their existing wide format printers to produce soft signage rather than investing in the more specialised dye sub printers.

There are a number of reasons for this, though the chief barrier for most sign makers is the additional investment needed for a heat press or calendar to complete the dye sublimation process. Add in finishing equipment such as a sewing machine and it can mean spending £50,000 or more. Other issues include having to set aside the floor space and find staff with the necessary skills, particularly for the finishing.

The other issue is the availability of suitable media, as Phil McMullin, Epson UK’s sales manager for pro graphics, explains: “In my experience with the sign industry, those sign makers that have already invested in solvent printers are finding that the array of media that’s available has now exploded and there’s a good chance that they can produce most of what they want on their existing equipment.”

Indeed, most resellers report healthy sales of coated textiles for eco-solvent printers. Many solvent vendors are privately grateful to HP, which has pushed its latex printers for textile use, making print buyers more aware of the relative advantages of soft signage and inadvertently encouraging media manufacturers to develop coated products that are equally suitable for solvent and UV use as well as latex.

Spandex, for example, sells a range of textile materials that includes flags, canvas and banners, suitable for use with solvent, latex and UV printers. Steve Jacques, Spandex UK’s consumables sales manager, estimates that the sales of textile materials is growing by “about 20 percent year on year over the last three years.”

However, although there is a reasonably good choice of coated textiles they do tend to cost more than the uncoated media that can be used with dye sublimation. This in turn means there is a lower profit margin compared with using more conventional materials so less incentive for a sign maker to persuade a customer to try a textile banner over, say, a PVC vinyl, where that sign maker can offer an extremely competitive quote.

This might also explain why most of the growth in textiles has been in garments and furnishings. That said, the use of textiles varies from country to country, with most European countries, particularly Germany and Spain, having embraced soft signage enthusiastically for over a decade.

Other countries, such as America and the UK have been slower to reap the benefits, largely for historical reasons because buyers have been happy to specify conventional materials like PVC. However, as Mike Horsten, European marketing manager for Mimaki, notes: “In the last five years the UK has been catching up because larger retailers have looked for alternatives.” Horsten also says that the UK, alongside the Netherlands, is a big market for flags, which he attributes to local planning rules.

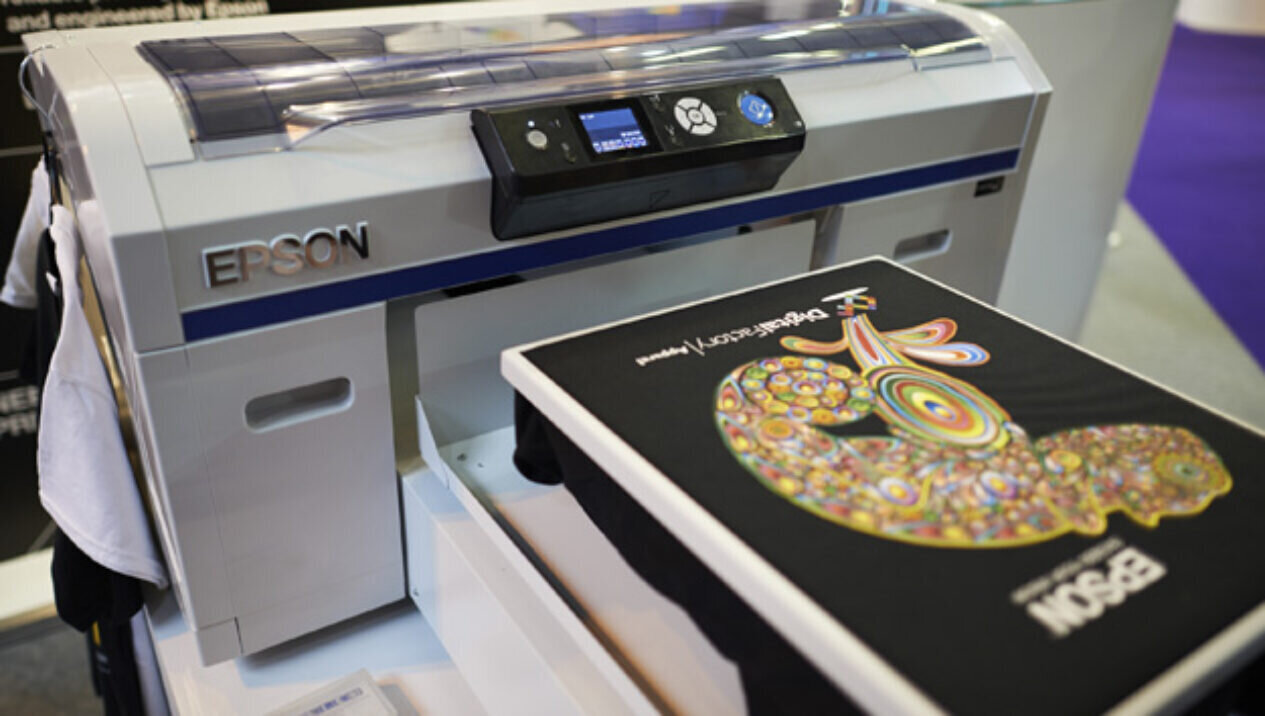

As well as the larger dye sublimation printers, Epson has also developed this F2000 t-shirt printer, which allows a sign maker to test out this market for a smaller outlay.

Most vendors believe that there is a huge opportunity in dye sublimation but that sign makers can only realise this if they specialise in one area. Thus McMullin says that Epson has found that its wide format dye sublimation printers are mostly going to high street retailers that want to produce branded garments with a very short lead time, as well as companies producing promotional items such as tote bags, mugs and tee shirts.

Some sign makers have used dye sublimation to develop specialised side lines such as producing flags or table cloths. But many printer vendors believe that the future growth in soft signage will come from solvent and latex printing, and will depend on an increasing variety of suitable media and, of course, lower prices for those materials.