Signage

Sustainability

Wide Format Printing

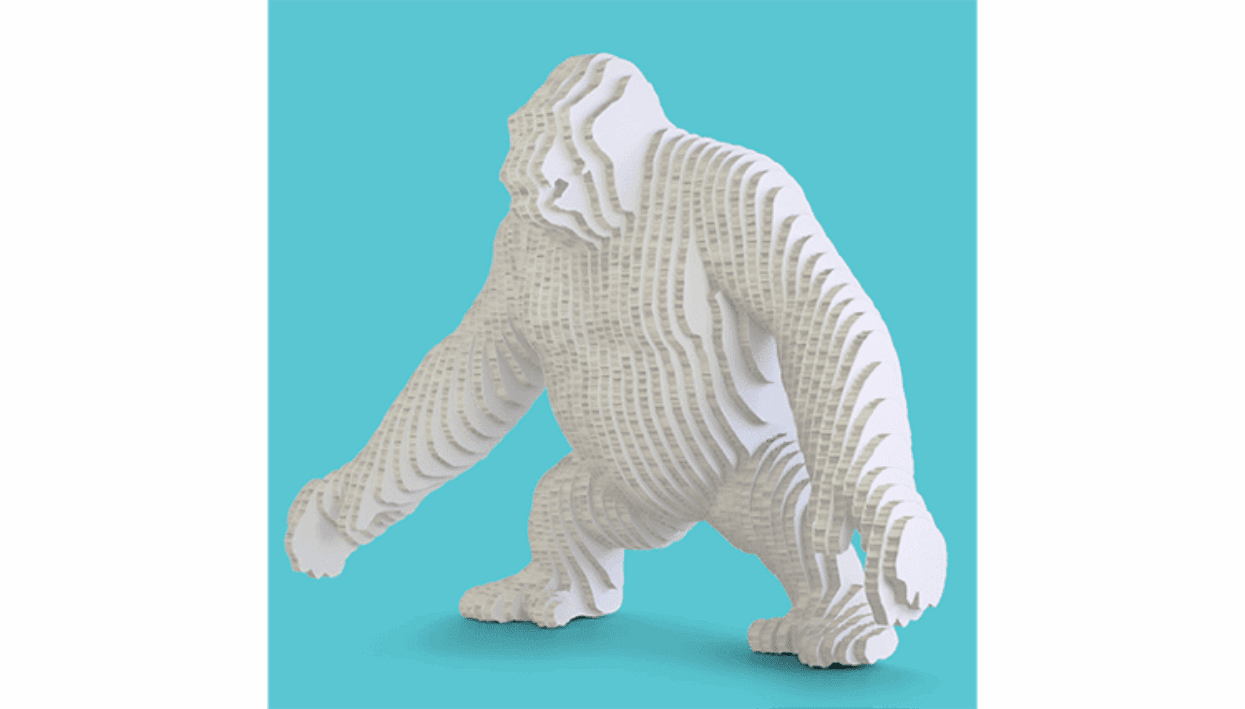

Sustainable alternatives to plastic substrates 3: Dufaylite

Author

FESPA Staff

Published Date

28/04/2020

Become a FESPA Member

to Continue Reading