3D Printing

Sustainability

Textile Printing

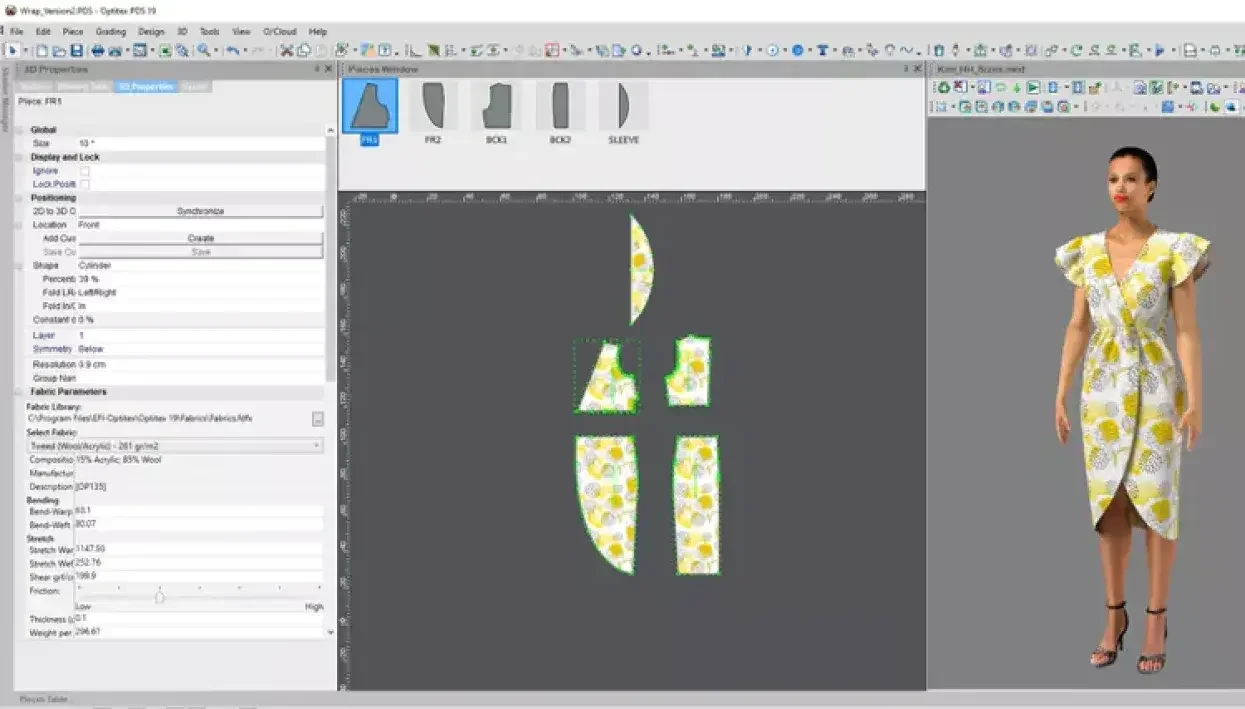

2D design and 3D visualisation in fashion printing

Author

FESPA Staff

Published Date

18/09/2020

Become a FESPA Member

to Continue Reading