Digital Printing

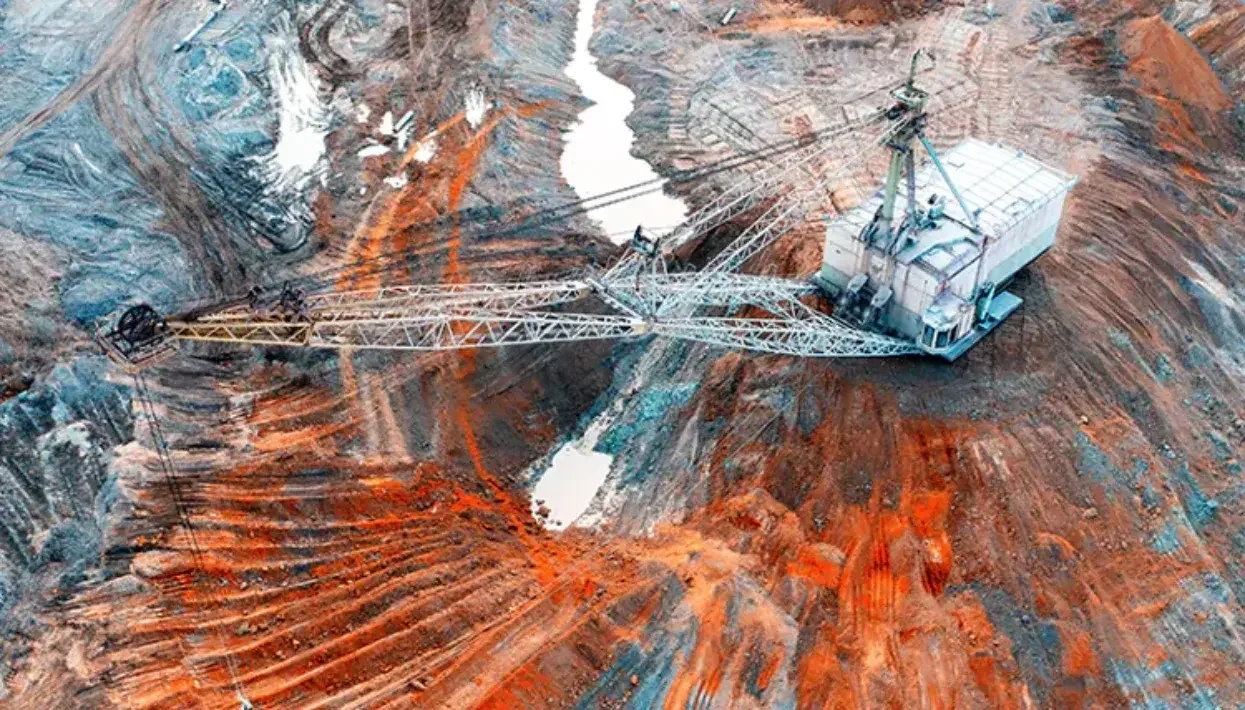

The hazards of rare metals in printing

Author

FESPA Staff

Published Date

22/08/2022

Become a FESPA Member

to Continue Reading