The global label printing market is a booming segment, expected to reach $47 billion in 2024. Short runs are driving this dynamic growth, fueled by e-commerce and product variation. Digital printing makes market entry feasible for print shops, allowing them to offer customized, sustainable labels by leveraging existing equipment or specialized short-run presses while ensuring regulatory compliance.

Label printing is expected to continue to develop dynamically in the coming years. This has been predicted by analysts from Research and Market back in November 2023. In their Print Label Global Market Report 2024 , they expect a further increase to roughly 67 billion US dollars worldwide by 2028, an annual growth of almost 5%.

Label printing is therefore keeping pace with the broader packaging market. This also includes printing on corrugated, cardboard, flexible materials such as paper, as well as rigid materials and objects such as bottles, plastic or metal. For the packaging market, which is currently estimated at around USD 365 billion, Global Market Insights expects a CAGR of 5% until 2032.

CAPTION: The recently introduced Epson label printer ColorWorks C8000e prints full-colour labels at up to 300 mm/s on paper, films and plastics. Image Credit: Epson

CAPTION: The recently introduced Epson label printer ColorWorks C8000e prints full-colour labels at up to 300 mm/s on paper, films and plastics. Image Credit: Epson

Big players dominate the market

Today, colour labels are produced using analogue processes such as offset and flexographic printing, digital inkjet, e-ink and toner printing as well as hybrid. For hybrid labels, basic parts of the motif are usually printed with analogue technology, while local or seasonal variations get added in digital print.

Packaging for fast-moving consumer goods is produced in millions of copies. The world’s largest packaging printers are often located outside the European Union, for example in the USA, India and, increasingly, China.

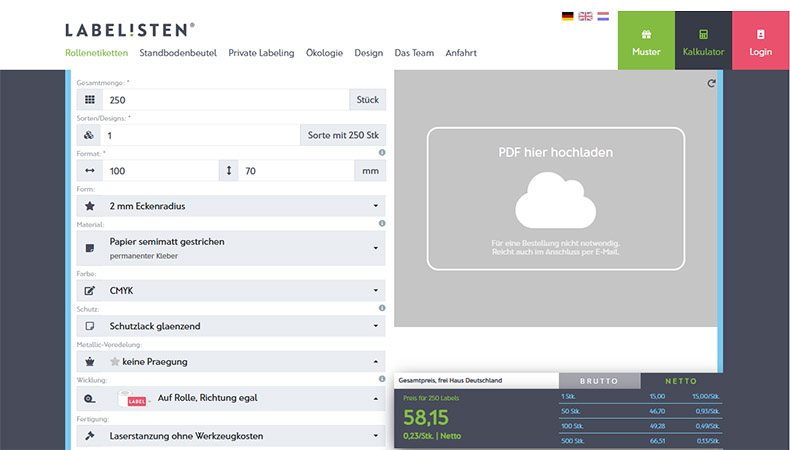

In contrast, label printing in small quantities is more regionally, in production as well as in demand. Web2Print is playing an increasingly important role. Providers such as Labelprint 24 , Labelisten or Etiketten-drucken offer many different labels in short print runs. But even online print shops with a wider range of products such as Wirmachendruck have a large selection of labels on rolls or sheets on offer.

Online providers address a very varied target group, ranging from private customers and local associations to cottage industry and smaller companies. As a result, often print data may not be delivered in profession quality.

Online editors try to anticipate and resolve data delivery problems with online editors, where customers may design labels directly in the browser. In the background, the software creates a printable PDF, already optimised for the selected printing press.

CAPTION: Labels in short runs are also becoming increasingly important for the food industry. Image Credit: S. Angerer

CAPTION: Labels in short runs are also becoming increasingly important for the food industry. Image Credit: S. Angerer

Small Labels 1×1

Stickers, whether from a roll or on sheets, are always constructed in the same way (from bottom to top):

- Carrier material (liner)

- Adhesive layer

- Carrier/label material.

In addition, there is usually a protective layer such as a laminate or varnish. The carrier material ensures that the label can be easily removed, using a silicone layer. The adhesive layer is typically made on an acrylic or rubber basis, with the glue available as removable, semi-permanent and permanent adhesive. In some cases, labels in small quantities may also use cling film as a base.

When it comes to label print material, there is always a choice between paper-based and plastic films. For outdoor use and for a humid environment, films made from PET, PE and PP are required. If the label is also to be seawater-resistant, PVC remains the first choice. Labelprint, recycled, dyed, metallised or natural paper is best suited for a dry indoor environment.

Especially for labels in short runs, it is also important to consider other requirements. For example, laminate or varnishing can mean that a label is no longer suitable to be written on or marked with a thermal transfer printer. This can be a major challenge if, a best-before date must be applied at a later stage.

Enter the label market

Many printers already own the required machinery to enter the label print market, as self-adhesive films can be printed with UV-curable, Latex, Eco Solvent or water-based inks on any roll-to-roll printer. With a print-and-cut device, for example from the Roland DG Tru VIS LG and LM series, this can even be done inline. After all, there is not that much of a difference between a sticker and a label.

Machinery designed specifically for label printing in short runs, usually work with pre-cut substrates on rolls. For example, the recently introduced Epson ColorWorks C8000e prints labels from 2.5 to 10 cm wide in full colour at up to 300 mm/s on paper, foils and plastics.

However, when it comes to label printing, even in small print runs, it is not only about technical equipment. Especially if labels are to be used for food or cosmetics, they must also meet certain requirements. For example, inks must be low-migration and non-toxic. In addition, packaging printing is also facing increased demand for green and sustainable products.

There are plenty of PVC-free films and papers made from renewable raw materials such as grass or bamboo for label printing. But especially for small print runs, the customer base is often very price sensitive.

CAPTION: The Franconian online label printer Labelisten offers short-run labels and pouches.

CAPTION: The Franconian online label printer Labelisten offers short-run labels and pouches.

Is it worth getting started with label printing in short runs?

Packaging and label printing are among the few segments in the printing industry that are expected to continue to grow in the coming years. Smaller household sizes and growing requirements for product safety and labelling ensure that short-run labels will continue to be in demand also in the next few years.

This results in an exciting market and opportunity for printers. This is especially true if a printer can act as a sustainable supplier for local production companies. Label printing can also be a good way for printers with an existing Web2Print offering to expand their range of products and services in an uncomplicated way and thus expand their revenue.