ISO 12647/2 and Fogra 51 provide essential standards for consistent colour management in wide format printing, bridging the gap with offset litho. While they may restrict the full gamut of digital presses, they offer a framework for predictable, high-quality output and client communication, turning compliance into a strategic advantage for printers.

ISO 12647/2, together with Fogra 51, underpins colour control and consistency in modern printing workflows, particularly when bridging offset litho standards with wide format digital print technologies. In recent years, the shift towards digital and wide format printing has demanded rigorous colour management, bringing these standards into sharper focus for print service providers aiming for offset-like outcomes and predictable colour reproduction across diverse substrates.

ISO 12647/2 – The Bedrock of Colour Consistency

ISO 12647/2 specifies process control parameters for halftone colour separations, proofing, and production prints in offset lithography. While originally designed for offset litho, its approach to tone value increase (TVI), ink sequence, and substrate specification provides a benchmark for digital platforms seeking consistent output, especially as clients grow to expect parity between offset litho and digital printing.

The standard’s requirements ensure that colourants, TVI curves, paper white points, and measurement techniques are unified, minimising variability and enabling digital printers to match offset proofs and production prints as closely as possible. In today’s wide format digital landscape, the pressure to deliver short-run, variable, or bespoke jobs with reliable colour increases the importance of ISO 12647/2 compliance.

Fogra 51 – Setting the Reference for Premium Coated Papers

Fogra 51 forms the characterisation dataset for PS1 premium coated paper under ISO 12647/2:2013, reflecting shifts in substrate manufacturing – particularly the prevalence of optical brightening agents (OBAs) to enhance apparent whiteness. Measurement now requires M1 spectrophotometry to more accurately account for paper fluorescence, aligning proofing papers and colour profiles with real production stocks.

In wide format digital print, Fogra 51 provides a standardised colour space (CMYK LAB values and curves) against which printers can characterise and calibrate devices, ensuring that client proofs, test forms, and final prints maintain uniformity and a contractual assurance of quality.

To digress for a moment, there is new beta version of the coated paper and broad profiles which does cover the Fogra 51,(PSO coated v3.icc) used in Europe, and the ‘G7’ (GRACol 2013 CRPC6.icc) used in the USA. This should help those who print for both markets.

The Fogra version will be ‘Fogra 62’, the icc profile name has not been decided.

This is the name of the ‘beta’ profile which you are free to use:

UCD_PremiumCoated_ISO12647_2_2026_beta_v4.icc.

https://www.color.org/ucd4test.xalter

Application in Wide Format Digital Printing

The uptake of ISO 12647/2 and Fogra 51 in wide format digital printing is partly a response to client demands for offset-matching colour and the ability to replicate branded or critical graphics across multiple devices, print sites, and substrates. With wide format presses, as with offset, process control metrics are crucial; calibration methods, profiling routines, and proofing strategies are built around these standards to assure the market that digital prints can meet rigorous expectations.

Print service providers now harmonise digital workflows using Fogra Media Wedges, referencing Fogra 51 datasets and measuring output according to ISO 12647 tolerances (ΔE specifications), to secure customer trust in reproduction quality.

Colour Gamut Challenges in Wide Format

Despite these advances, issues persist. Digital printers – especially inkjet and toner-based wide format devices – may feature wider or differently-shaped colour gamut’s compared to offset processes or Fogra references. While this can allow richer colour in practice, the need to match proofs or offset references means some of this expanded gamut must be ‘clipped’ during colour management. This is particularly problematic for colours outside the range of standard CMYK – such as vivid reds, blues, or brand-specific hues.

Further, the underlying print substrate is often less predictable: wide format jobs frequently use non-standard materials and varied finishes, introducing variability in ink absorption, paper white point, and fluorescence (OBA content). Maintaining ISO/Fogra compliance demands careful linearisation, media calibration, and using proofing stocks that truly represent the production substrate.

You may wish to use the maximum colour gamut of you press for some work that does not require a match to the ISO standards. For this you can use the maximum gamut of the press for the device icc profile and the output icc profile

Note this system may vary press-to-press as the device icc and gamut may be different resulting in a different result.

A solution to this is the use of a wide gamut CMYK icc profile as the output profile so normalising the wide gamut output.

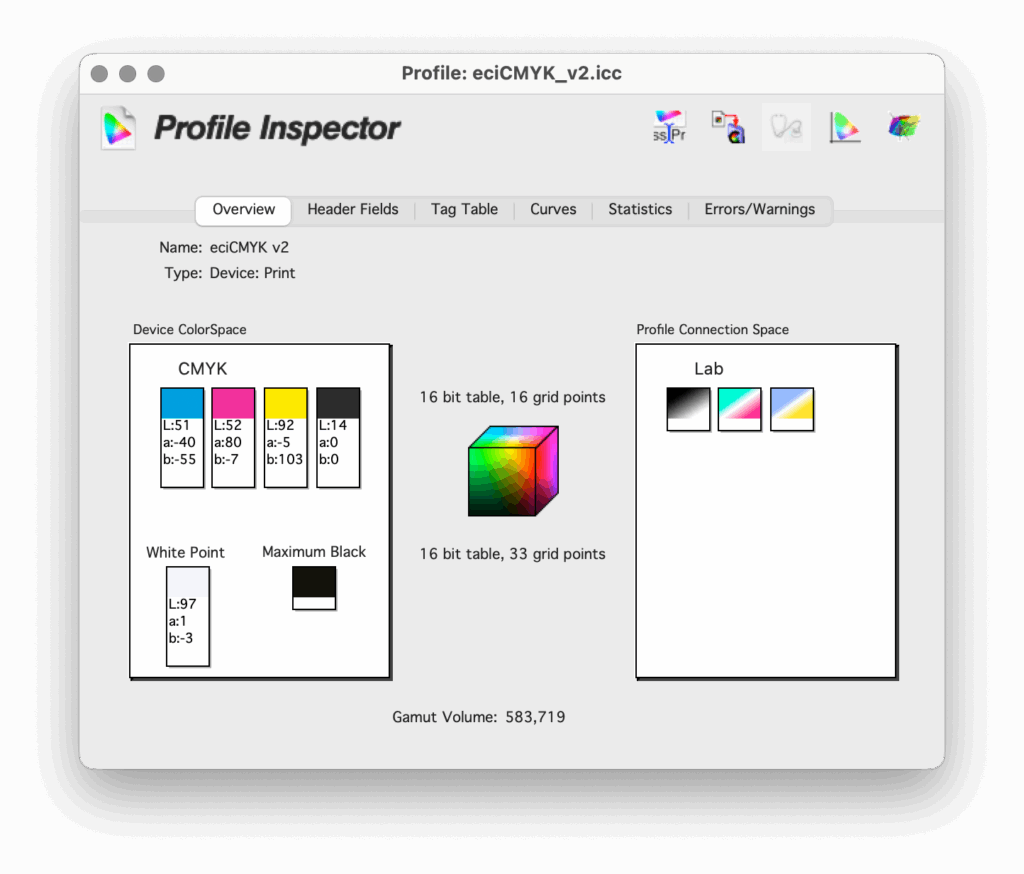

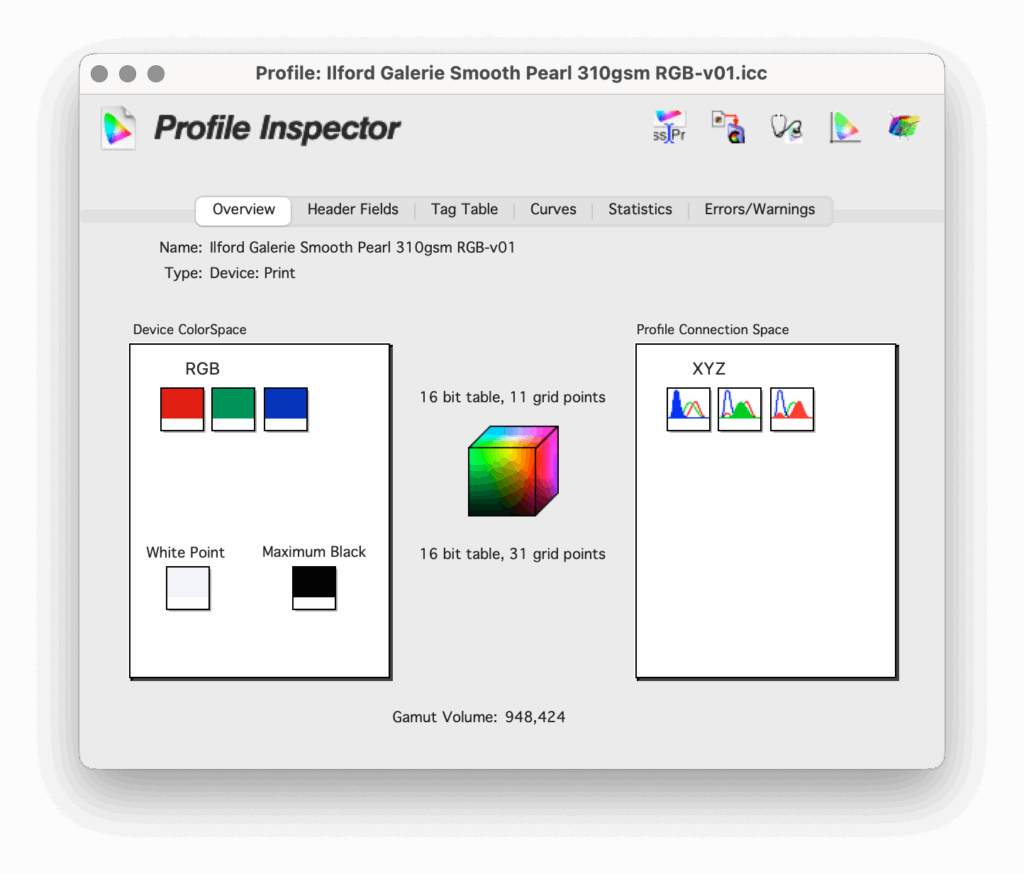

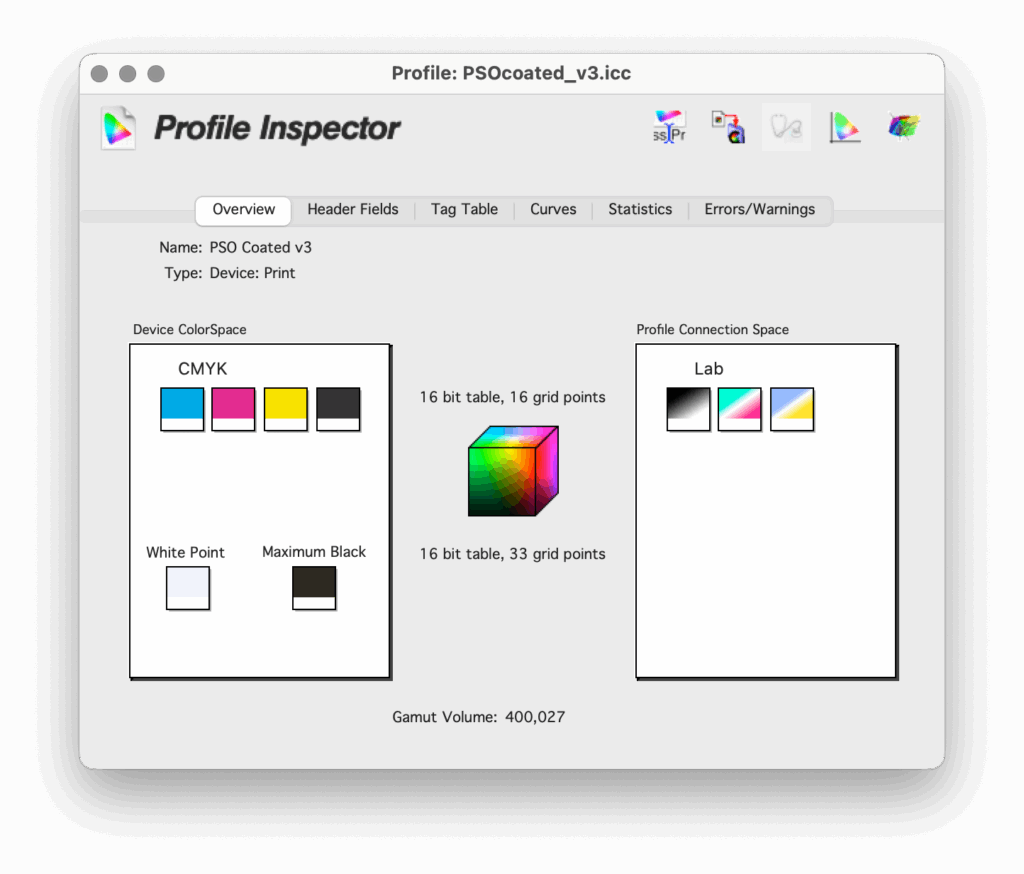

Below are details of the gamut’s of PSO coated v3, the eciCMYK wide gamut (Fogra 59) and a RGB gamut device icc based on a fine art paper.

The Realities of Implementation

The move from Fogra 39 to Fogra 51, and the ISO 12647/2:2013 revisions, introduced more realistic benchmarks for modern, OBA-rich papers but also posed challenges. Instrumentation upgrades to support M1 measurement (which better accounts for OBAs) are costly and not universally adopted, slowing market transition. Legacy hardware, variable press conditions, and diversity in media types all compound the challenge, explaining why full compliance remains an aspiration for many rather than a universal reality.

Additionally, while ISO/Fogra provide the language for industry standards, practical colour management in wide format additionally requires robust software tools – spectral profiling, proofing solutions, and process control systems that can interpret these characterisation datasets in a way that is actionable on the ground.

Beyond Standardisation: Managing Expectations

Despite its limitations, the industry’s adoption of ISO 12647/2 and Fogra datasets has delivered appreciable benefits in client communication, colour appearance, and process predictability. Proofs become a contract proof , media wedges a guarantee, and the application of tolerances (average ΔE ≤ 3, maximum ≤ 6) a tool for negotiation and quality assurance.

Yet, as often discussed in colour management circles, the nature of wide format work – from banners to bespoke displays – means creative latitude, substrate variability, and increasingly adventurous clients will continue to push the boundaries of what standards can assure. The goal is not simply rigid compliance, but the ability to deliver on client expectations – consistent, predictable colour – even as technologies and demands evolve.

Conclusions

It’s evident that ISO 12647/2 and its Fogra 51 dataset and PSO coated v3 as the icc profile, have become critical pillars for colour management in wide format digital printing. However, their implementation is not without nuance.

I have witnessed printers transition to digital wide format, striving to meet the same colour standards as offset. ISO 12647/2 isn’t just an aspiration, but a contractual reality. Its underlying message: control your process, understand your subtract, manage your colour. Fogra 51, built around modern media with high OBAs, has nudged the market to look at their substrates with new eyes – and their measurement devices with new budgets.

But real-world colour management isn’t about standards alone. It’s about matching the intent behind those numbers to the expectation in your client’s mind. Wide format printers work with substrates that are as diverse as their clients – from textiles to films to board – and the Fogra references are a lifeline, not a straight-jacket.

Gamut issues? Yes, there are plenty. Digital devices can roar beyond the confines of offset litho CMYK, but unless printing on exotic substrates or using six/seven colours, the boundaries set by ISO and Fogra may still apply for proofs and contractual work. We clip the excess, manage the expectations, and ensure that designers, brands, and marketers see what they expect. That’s the real art – and science – of wide format colour management today.

The future is bright, not just because of OBAs, but because of how the industry has embraced process control. ISO 12647/2 and Fogra 51 don’t solve every problem, but they’re the language we use to agree what ‘good’ looks like. And that’s how we deliver trust in print, no matter the device, ink, or substrate.

ISO 12647/2, Fogra 51and others have become indispensable standards as wide format digital print continues its rapid evolution. Their role in underpinning process control, colour consistency, and client confidence is profound, even as technology and creativity push the boundaries of what’s possible. Colour gamut challenges persist, shaped by device capability and substrate choice, but the strategic application of ISO and Fogra datasets – and the pragmatic mindset of print professionals – ensures that consistency, quality, and customer satisfaction remain within reach.