Inkjet printheads precisely jet fluids, handling various ink types and viscosities. The main technologies are piezo-electric (using PZT material) and thermal inkjet (heating ink into vapour). There’s also continuous inkjet for high speeds and valvejet for large drops. The industry is seeing more R&D, driven by new industrial and 3D printing applications.

Inkjet printheads lie at the heart of the digital revolution as well as every inkjet printer, so it’s always useful to understand how these devices work. The purpose of a printhead is simply to place small drops of a given fluid as and when needed on a substrate. That could be an ink for a graphic arts application or a functional fluid, such as a coating, for industrial use, with most heads designed to cater for many different applications. The key characteristic is the accuracy in placing the droplets exactly where needed, which becomes more challenging at higher print speeds.

The printhead has to be able to handle the characteristics of a range of different fluids or inks. Many of the most common heads in use today are designed to run UV-curable inks but other fluids might be based on solvent, water or oil. Indeed, the steady growth of textile printing, plus single pass commercial printing, has led to increased demand for printheads that can handle water-based inks. The head and all the associated fluid management systems must be hardened to resist whatever chemicals are in these fluids, such as solvents that might eat away at the material of the head or water that might cause internal electrics to short circuit.

Increasingly, OEMs want to increase the functionally of their fluids, which the head manufacturers have to keep up with. In many graphics markets there’s a clear trend towards inks with a higher pigment loading, which should lead to lower ink consumption. Such inks generally come with a higher viscosity that make them harder to jet though there are many ways around this, such as heating the ink to lower its viscosity. However, most printheads are limited to handling viscosity up 10 or 20cP, though some Xaar printheads can handle fluids up to 100cP in viscosity.

Some printheads can recirculate the ink within the head to prevent particles within the ink from settling and to eliminate blockages around the nozzles. This is useful for certain inks, such as white that contains large particles, as well as for industrial uses where there may be a lot of dust and dirt in the atmosphere. Recirculation can also help to maintain the temperature of the ink, as it circulates past a heater.

The vast majority of wide format printers use piezo-electric drop on demand printheads. These rely on a natural occurring phenomena where an electric charge can cause some materials to change shape. Most of these printheads feature actuators built out of lead zirconate titanate, or PZT, because of its very efficient piezo-electric properties in changing shape to force the ink from the ink chambers, through the nozzles.

These piezo-electric printheads can be further broken down into two classes. Perhaps the most common type is bulk piezo, which uses a block of piezo-electric material. A good example of this is the monolithic block actuator developed by Kyocera. The Kyocera name derives from Kyoto Ceramics, and the company has used its expertise in ceramics to create a dense polycrystalline ceramic actuator using thin piezo-electric ceramic substrates. The result is a very thin piezo-electric actuator plate that measures 116mm long and 34mm wide with a depth of just 0.04mm, which sits above the ink chambers within the head. By precisely controlling the voltage applied to this actuator, through the waveform and drive electronics, Kyocera is able to subtly control the shape of this actuator to eject the ink from each of the ink chambers. Plenty of other printheads are also based on their own variations of the bulk piezo approach, including Ricoh MH5320 Gen6, Fujifilm Dimatix Starfire and most of Xaar’s printheads.

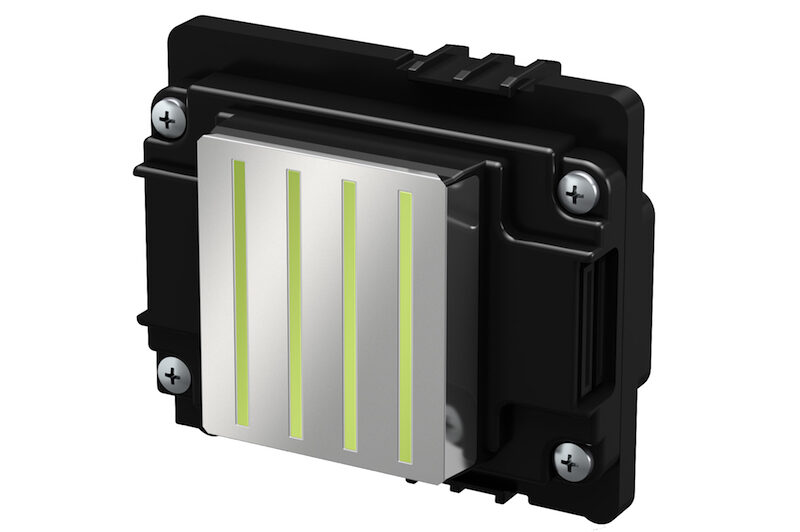

The alternative piezo-electric method is the MicroElectrical Mechanical systems or MEMs approach, which uses semiconductor technology to construct the actuator. In theory this allows for greater complexity and precision. There are two main approaches for adding the PZT to the actuators, with Fujifilm Dimatix favouring Sputtered PZT and Ricoh and others using Sol-Gel but both result in a very thin film of PZT. The silicon is built up one layer at a time, using photolithography to make patterns within these layers to create the channels for the electronic circuits and the fluidic management. Typical examples include the Fujifilm Dimatix Samba, Epson PrecisionCore and Ricoh TH5241.

Another common type of printhead is thermal inkjet, or TIJ, where the ink is heated until it forms a vapour bubble that forces the droplet out of the nozzle. This only works with water-based inks, such as latex or resin ink and is mainly used by HP and Memjet in wide format applications. HP also sells thermal printheads to other OEMs, mainly for use in coding and marking applications as well as for some graphics packaging printing. Thermal heads generally have a relatively short life and are regarded as consumable items. However, both HP and Memjet have managed to prolong the working life of their thermal heads in recent years. Canon also has TIJ technology but has mainly concentrated on desktop printers. However, Canon has recently developed TIJ printheads for a commercial production press and is about to launch an industrial label press with thermal printheads.

Then there is continuous inkjet or CIJ. This is not relevant to wide format printing but is widely used for coding and marking applications. It’s also the basis behind Kodak’s UltraStream printheads, which are used for its high speed commercial press, the Ultra 520, as well as for adding digital capability to web offset presses. The principle is that the ink drops are fired in a continuous stream that allows for very high speed jetting. Most of the ink drops are deflected away to be re-used so that only the drops that are required actually land on the substrate.

Finally, it’s also worth noting that there are some uses in the graphics market for ValveJet printheads. Ricoh, for example, showed a personalised tyre printing application at the recent Fespa Global exhibition in Berlin that used single nozzle valvejets for each colour. The principles behind the valvejet approach are fairly simple. There is a hole at one end of the fluid chamber, that is closed off by a valve. Ricoh is using a piezo actuator to open and close this valve. The fluid is supplied from a pressurised tank, so that when the nozzle is opened the air pressure is enough to force the drop out. The advantage is that it can jet large ink drops for high coverage, allowing for more functional inks with larger particles and with high viscosity above the 100cP range.

Looking ahead, there is a growing interest in using inkjet printing for industrial applications including also 3D printing. That means greater market potential for the printhead manufacturers, justifying more R&D that will ultimately lead to a greater choice of printheads for printer OEMs to work with.