Recycling advances

.jpg?width=750)

Laurel Brunner discusses the importance of sustainable printing and the neeed for printers to choose their substrates meticulously in order to lower their impact on the environment.

Given current anxieties about climate change, it is safe to say that recycling is on everybody’s mind. But like wide format digital printing, recycling is a business, an industry. It benefits from a massive and complex infrastructure one that’s been gradually put in place over many years to turn waste into raw materials suitable for secondary products. So far so simple. But the range of materials recycled and of the products into which waste can be turned, plus the complexities of collection, sorting and processing make this an extremely convoluted and not always environmentally friendly, business.

Print the sustainable choice

For players in the graphics industry, and especially for print buyers, including considerations for how products can be recycled as part of their investment choice, can be tough. It seems obvious to choose paper because as graphics professionals we know that it’s based on a sustainable resource: harvestable trees. We would like to think therefore that paper is the most widely recycled form of waste. However this is not even close to the truth, so we can maybe be a little more expansive in our substrate choices to include certain types of plastic. Plastics are the most recycled materials after asphalt, concrete and steel, mostly because the supply chains are in place to support most plastics recycling and reuse. Although printed paper products score high on the list of recycling volumes, the various sorts are processed differently so they tend to be treated as different categories. For instance cardboard has its own category, as do graphic papers and newsprint. The good news is that technology is helping to improve the efficiency of all types of recycling, plastics included.

Sorted

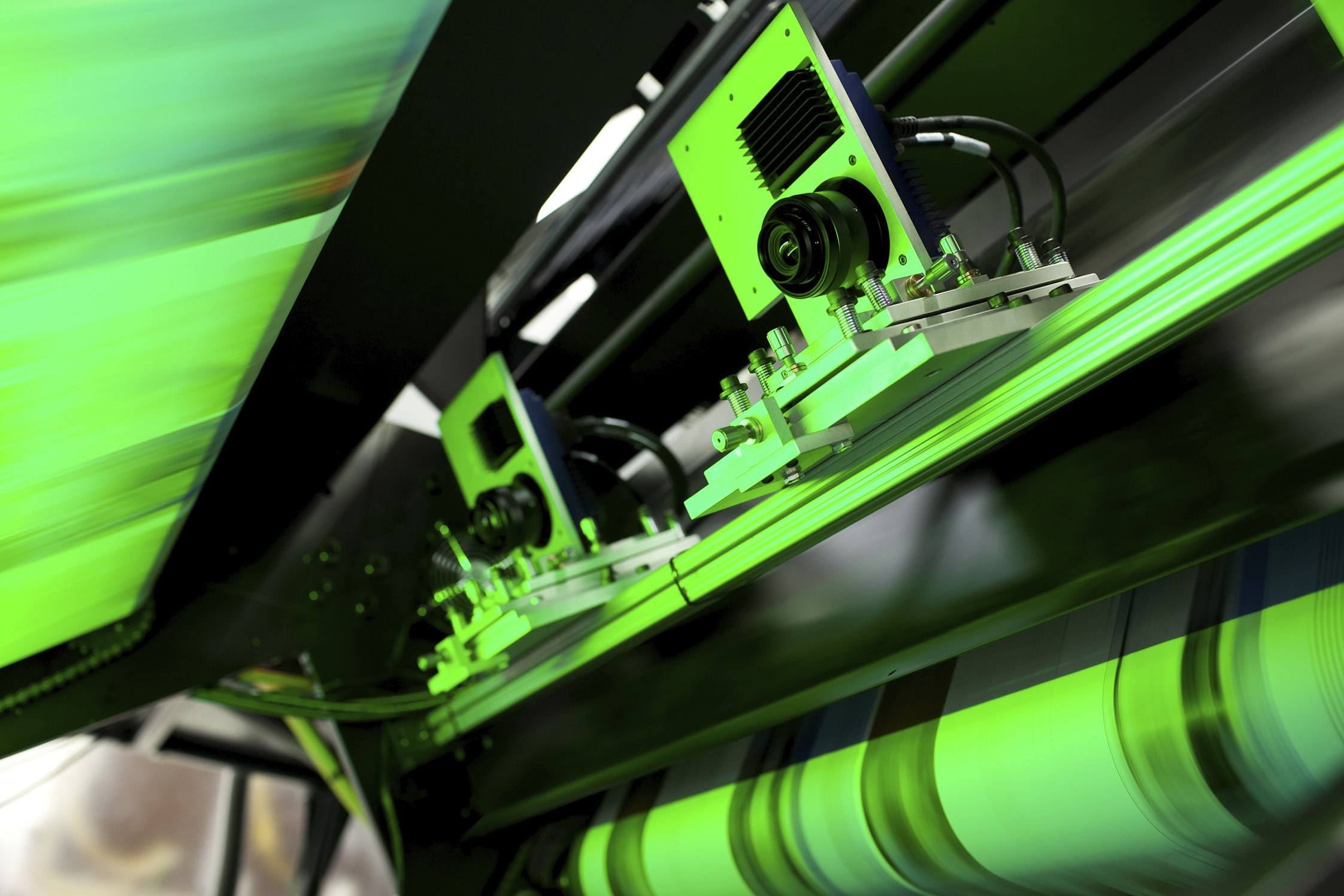

Optical sorting technology uses sensors and cameras to separate complex waste streams. It uses image analysis data to determine what should happen to a given material, so that it is sorted into the right reprocessing line. Objects in a conveyor belt can be inspected from above and below and classified according to accept/reject thresholds the operator can set. The use of optical sorting has great promise for paper recycling, which is becoming more urgent as the use of new digital printing techniques and ink recipes spread.

Light Fantastic

Nippon Paper in Japan has patented a means of sorting printed matter using light. The technique measures reflected light in order to identify printed paper waste that will be hard to recycle. Printed materials are identified by irradiating the surface of the printed materials and measuring the reflected light. Those that are likely to require multistage deinking or other processes can be removed from the waste stream. They can be routed for deinking and recycling using dedicated processes, or reprocessed into lower grade substrates such as packaging or board.

About The Data

Data analytics is another area where great strides are being made for recycling. Software developers are coming up with platforms that local authorities can use to encourage people to recycle responsibly and to trace those who are not doing so. At their most simple, such platforms provide tools that districts and people can then use for comparison, either with other areas or their neighbouring streets. Digital platforms provide the basis for data collection, community engagement, and waste management and recycling performance over time. This ought to lead to changed behaviours so that recycling becomes second nature, and poor waste management is recognised as antisocial.

Changing behaviours is fundamental to progress, and fortunately the problem isn’t one of innovation. It is rather one of consistency and providing incentives to develop new approaches to recycling that people can support. This is as much about our habits and convenience as it is about technology, as we all know. Sorting for kerbside collection or taking separated waste to a drop-off point is easy, as long as the infrastructure is in place for it. If the infrastructure isn’t there or if it is complicated, we are less inclined to do the right recycling thing.

Going Wild

These are all considerations when planning a wild format digital print project, and they have to factor into the planning from the start. The easiest answer for creators and designers is to specify substrates that can be recycled, and to include instructions to use such materials as part of the design brief and to make sure that sustainable choices are made wherever possible. Many magazine publishers for instance, such as the Economist Group use bioplastic sleeves when sending titles to subscribers along with instructions to compost the waste plastic, rather than treat it as waste.

Could Do Better

We must all face the fact that our current recycling models need improving. The question is how to make them better and more efficient. Technology and changing behaviour play their parts, but we need to think much more creatively to solve the problem. For instance perhaps the burden of reuse should be shifted onto the producers of the materials, say the substrate manufacturers or distributors, or the printers. We are already seeing small signs of how this model can work in the graphics industry. Agfa Graphics sells the coatings on its printing plates, rather than the plates. The company has in place a system for collecting and recycling used plates, so its customers only pay for the coatings and essentially rent the aluminium that carries it for a few weeks.

Such a model puts the onus on the manufacturer or distributor to take responsibility for the recycling, so it might not work in all sectors of print. But in the wide format digital printing sector such a model could work for substrates that are particularly hard to recycle. Maybe there is someone somewhere who could work out a viable business model, if the local raw material collection was sorted or delivered to a processing plant.

It Starts With You

It’s clear that like consumption, recycling has to function at the grass roots, with people, with businesses and with local governments. Ideally it should function within national and international frameworks. At the very least we should be following common principles and expectations, and we should be able to tell people about what happens to print media waste.

Encouraging common best practise however depends on what is considered to be best practise. Is sending paper and board waste to another country, with the concomitant transport and shipping emissions best practise? If it supports jobs within the supply chain, perhaps it is. For recycling to be a joined up business, we must accept that commercial imperatives and even legislation have to be considered. Commercial interests, like it or not, will trump environmental impact mitigation every time, which may be an argument for regulating recycling in support of circular economies. Change needs government support, internationally, nationally and locally, so that the responsibility to recycle sits squarely at the heart of society and economies.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Are analytics services worthwhile for wide format printing?

Nessan Cleary shares how press manufacturers are increasingly offering machine analytics services and shares if these are good value for money in the wide format sector.

Smart factories and customisation technology explored at Personalise Make Wear 2024

FESPA's Textile Ambassador, Debbie McKeegan speaks to industry specialists at Personalise Make Wear at Personalisation Experience and Sportswear Pro 2024 held in Amsterdam. Each day of the exhibitions Debbie hosted a fire-side chat with these specialists to discuss various industry topics. During this Fire-side chat with Antigro, Caldera, Print Logistics, Inkcups and Kornit Digital they discuss the role of digital technologies in personalisation, reshaping the supply chain, the future of manufacturing and more.

The pros and cons of Digital Signage and Printed Signage

Sonja Angerer discusses the pros and cons of both digital signage and printed signage. Current developments such as artificial intelligence and spatial computing are changing the situation once again. How will this shift affect printers?