Epson seeks textile growth with new dye-sublimation launch

Rob Fletcher speaks to Epson UK regarding their new SC-F6300 dye-sublimation printer for textile producers, photographic studios and promotional goods businesses.

Digital print giant Epson has moved to enhance its presence in the global textile printing market by rolling out a new dye-sublimation printer in the form of the SC-F6300.

Developed with a specific focus on textile producers, photographic studios and promotional goods businesses, the new machine builds on the success of its predecessor – the SureColor SC-F6200 – offering improved user productivity and reduced downtime.

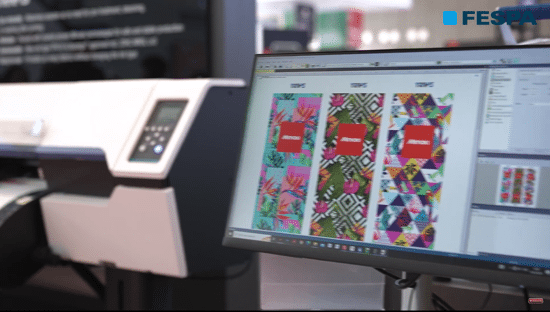

The SC-F6300 will be supplied with a software bundle that includes Epson Edge Print RIP, Epson Edge Dashboard Support, including EMX profiles, and Epson’s LFP Accounting Tool. Epson said that by including these products as part of the package, it will help SC-F6300 users to run more efficiently and allow them to better analyse costing and profitability.

Speaking to FESPA.com about the new launch, Phil McMullin, sales manager for Epson UK, said that the new machine will help print service providers access a range of key growth markets within the textile print sector, as the device offers an affordable option to businesses of all sizes.

“Digital print still has a very small percentage of the global textile market so we see a huge opportunity for all our textile printing technology, not just dye sub,” McMullin said. “That said, the low capital cost and small footprint of the F6300 makes it ideal for even small businesses, so we see demand staying strong for many years.

“The versatility of Epson dye sub printers means that it can be used in a wide array of different markets. Textile applications such as fashion and bespoke décor are obvious mainstays as well as sampling and stretched exhibition graphics”

Aside from traditional textile products, McMullin said that the SC-F6300 can also be put to work on a number of applications in various other markets, including the growing personalised print sector.

“Rigid substrates such as coated aluminium panels, table tops, mouse mats and mugs will be other products, plus the addition of a vacuum oven gets you into the printed 3D arena, covering products such as ceramics, cutlery, jewellery and helmets,” McMullin said.

“We’re confident that we’ve designed a dye-sublimation printer that will keep businesses running at peak efficiency and requires little user intervention.”

McMullin also said that Epson will continue to work on bringing new solutions to market to help give its customer an advantage over their competition.

“Epson spends around $1.5m (£1.2m/€1.3m) per day on R&D with investment in both ground-breaking technologies and also improvement of existing product offerings,” he said.

“We see the digital textile market as having huge growth potential, and you will continue to see a raft of product launches from Epson, in all application areas, over the next 24 months.”

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

What does Artificial Intelligence mean for the Design and Print Industry

Today, Artificial intelligence is already built into many products even though at times it is not noticeable. Looking towards the future, the growing presence of AI will change the design and printing industry forever. Sonja Angerer shares how you can successfully future-proof your business.

How to minimise water usage in textile printing with the Mimaki TRAPIS

We speak to Arjen Evertse, General Sales Manager EMEA and Marc Verbeem, Supervisor Product Management from Mimaki Europe about the Mimaki TRAPIS, an environmentally friendly, two-step, waterless textile transfer printing solution.

How to decorate hats with anything, anywhere including 3D embellishments

We speak to Andy Rogers, Marketing Director at Stahls' UK & Europe about decorating hats and specifically the 360 IQ hat press at FESPA Global Print Expo 2024 at the RAI in the Netherlands.

How to increase heat transfer efficiency with consistently accurate positioning

We speak to Andy Rogers, Marketing Director at Stahls' UK & Europe about the Pro Place IQ and the technology behind it. Andy shares how the Pro Place IQ projects the image on the screen, down onto the platen.