Transmission densitometer: what is it and how should you use it?

How this piece of kit can play a role in improving output quality.

Print and finishing machines might be the obvious place to look when you’re looking to upgrade your tech to improve output and gain an advantage in the marketplace. But with digging a little deeper, you could unearth is a whole treasure trove of options.

You may not immediately think ‘transmission densitometers!’ – but this specialist piece of kit plays a significant role for certain types of printers.

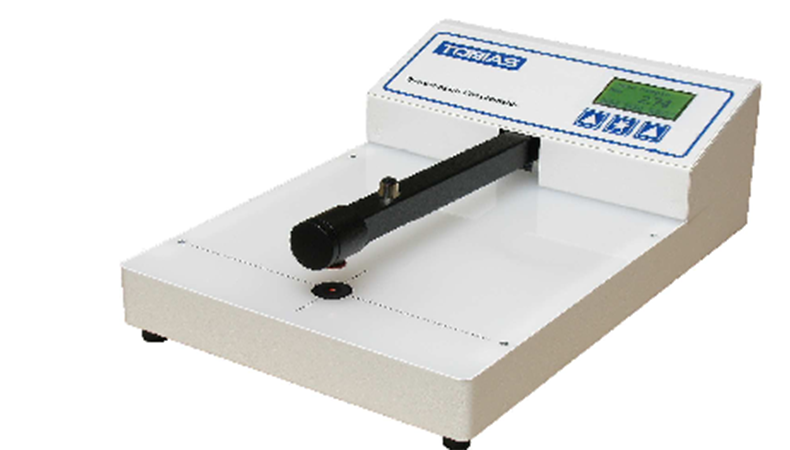

The Tobias TX1000 has a 7.5in throat to measure large samples

What is a transmission densitometer and how do they work?

Put simply, a transmission densitometer is a tool that passes light through a material to measure its opacity.

This will catch the attention of any printers working with films positives in the screen making process.

How do they work?

Lincoln Swann, Technical Director at Cherlyn Electronics, a company that specialises in colour control equipment, sets out the typical process.

“For many print processes a transparent film mask is created as an intermediate stage, with this mask or positive of the image to be printed and then photo-exposed onto a screen emulsion,” Lincoln says. “Within screen printing specifically, the mesh screen may be exposed using a film in this way.”

Who needs a transmission densitometer?

John Finley, Service Manager at Tobias Associates, which specialises in supplying densitometers, says said: “In my opinion, the transmission densitometer is only useful to printers still using film in their production process or are trying to maintain quality control over special stock or trying to maintain material deposits over clear stocks.”

However, spectrophotometers have reduced in price and become more accessible, and are now replacing transmission densitometers in the press room.

John also states that reflection densitometers – different to transmission densitometers – common in pressrooms for measuring ink density on paper to allow users to quality-control any incoming stock. However, despite their rather long-winded names, He says both models of densitometer are very easy to use and only take around five minutes to master.

John and Lincoln both state that a transmission densitometer can still be of great use to any company working with a film, as it can be used to help control both dot gains and exposure times on film material.

FESPA has run several workshops in the use of transmission densitometers to correct TVI (tonal value increase or dot gain) on film positives as it is very important to ensure the correct curves are used in production.

How much does it cost – and is it worth it?

So, we’ve established what they do and the sort of company they are suited to, but as is the case with any sort of new investment in kit, the decision may come down to cost. Do you want to be shelling out hundreds or thousands on pounds on a transmission densitometer, and is it even worth it?

Lincoln offers the example of the Ihara T5+ model, which usually costs around £1,500. He says that when the printer weights up the cost against the value of both quality improvements and job control, then it is definitely worth at least considering investing.

The Ihara T5+ transmission densitometer usually costs around £1,500

John takes a similar viewpoint, saying that as the main job of a transmission densitometer is to improve and maintain quality, this can only be seen as a positive addition to your production portfolio.

He adds: “If you are a printer that wants to produce a highly consistent job that is repeatable from sheet to sheet and job to job, it is imperative that you have the equipment to ensure process control.

“Also, printing more accurately can save on paper, press time and rejected jobs to name a few. Better quality can also generate more business and give you an edge over your competition.”

In terms of transmission densitometer models Tobias Associates can offer to the market, John says there are options to suit various budgets, with its TBX models starting at $2,650 and rising to $2,950 (around £2,000 to £2,250) , depending on features.

FESPA’s Head of Technical Support, Graeme Richardson-Locke, says: “As these devices have been around for many years, it’s worth looking for second-user calibrated instruments from suppliers and buyers should be aware that simply buying from ebay may result in an unusable purchase.”

What if I can’t afford one? Is there another way?

While this kit may offer you a number of advantages, it is no secret that the modern printing company is under pressure to save money, which could include cutting back on new kit. However, John and Lincoln agree that when it comes to transmission densitometers, they play an important role.

John says: “The only workaround for not having a densitometer is hoping your employees have extraordinary colour eyesight. Running jobs by eye is hard and fatiguing. The eye can also be tricked by the lightness and darkness of the surroundings of the area you are looking at.”

Graeme says: “There is no workaround as this device presents the only method to scientifically control the inconsistencies born out of incorrect TVI or dot gain.”

Lincoln agrees: “Densitometers are control tools – they can measure better than the human eye. Often a visual inspection is additionally used; if so, this should be conducted under controlled lighting as some colours change with lighting conditions.”

Put simply, if you are looking to improve the output of your screen printed work, and you don't want to break the bank, then transmission densitometers may be the way to go. Although not suitable for all types of print business, for those that are working with film positives, the benefits of this kit more than outweigh the costs and will save you money in the long run.

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Topics

Recent news

New sustainable materials at Sustainability Spotlight

Sustainability Spotlight returned by popular demand to FESPA Global Print Expo last month in an exhibit curated by The Good Factory.

Sportswear Pro: building ‘Brand Me’

After the success of the inaugural Sportswear Pro last month, we spoke with panellist and personalisation expert James Lawrence-Jones about the most exciting revelations at the event.