Industry 4.0: expect the unexpected

Will the new industrial revolution wreck or restart the print industry?

There have been four industrial revolutions:

Industry 1.0 from around 1760: Mechanisation and steam power

Industry 2.0 from around 1870: Gas and oil energy, chemical synthesis, mass communication, production and transportation

Industry 3.0 from around 1970: Nuclear energy, computerisation, telecommunications and information technology

Industry 4.0 from around 2000: Internet, globalisation, digitalisation, the Industrial Internet of Things

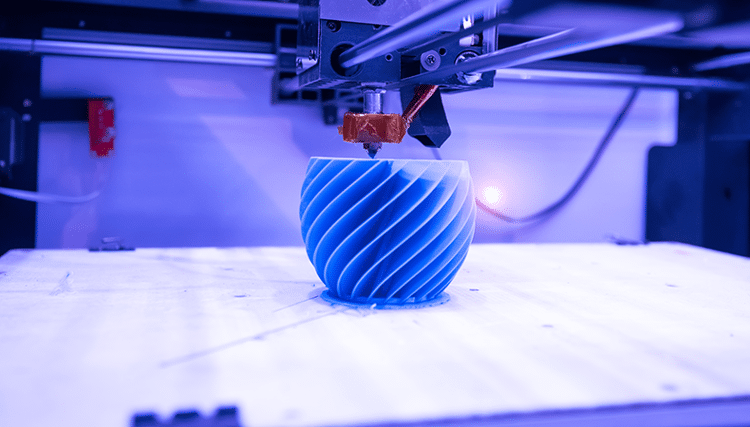

Industry 4.0 is the fourth industrial revolution. It is dissolving the boundaries between the physical and digital realms through the Internet of Things (IoT), through 3D printing, artificial intelligence, machine learning and interconnected production lines. It is not driven, as in the three previous industrial revolutions, by the discovery of a new source of energy, but by digitalisation and renewable energy.

The possible gains for industry and society as a whole are huge: the democratisation of industry, efficiency leaps in predictive maintenance, logistics cost savings and a cleaner, greener and leaner economy.

Printing 4.0 is a spoke on the wheel of the new revolution. Print service providers (PSPs) too are adopting new techniques and technologies to modernise their business while offering exciting new options to customers. As more PSPs switch their way of thinking and operating to mirror the mindset of the modern customer, the use of printed material is shifting back on-trend.

Revolutions are drastic solutions to social needs: climate change and the need for cleaner, low-energy, less wasteful industry are driving Industry 4.0. But too many are clinging on to the old ways, according to Professor Peter Cochrane of Cochrane Associates: “The big gains can only be realised by an industrial and supply chain revolution. Continuing to polish what we already have merely puts off the day of collapse.”

All attempts to create sustainable societies can “only be regarded as feeble”, says Professor Cochrane, if energy sources and transportation continue to pollute, and industries continue to operate at very low ecological efficiencies. But there are already signs that the revolution is gathering steam.

Prime solution

Professor Cochrane suggests that at the core of this complex situation is a “prime solution that occurs at the cusp of nano-tech, bio-tech, AI and robotics”.

He explains: “We can create the new materials and processes that far exceed the performance of everything we have today. It is here the amplification of limited human thinking, imagination and creativity occurs. The ability to create and recover materials at high efficiency, manipulate and form them at minimal energy, is the lynchpin of Industry 4.0.

“Pulling turbine blades from a single crystal, 3D and 4D printing of plastics, ceramics and metals to create manifolds and other complex forms are now common examples.”

How will this affect digital printing on flat sheet materials? “Some of the biggest material science advances are occurring in the creation of sheet metals, plastics, ceramics, glasses and fabrics employing nano-tech, bio-tech and coatings,” says Professor Cochrane. “Extraordinary strength, hardness, flexibility and performance, with high recoverability in nano steels, carbon-fibre forms, diffused plastic and printed ceramics have been demonstrated. Embedded electronics and hydrophobic coatings are also adding operational sophistication.”

Plotting a course through change

Peter Kiddell, former Director of the FESPA UK Association, says that Printing 4.0 is crucial to the continued development and success of print as a manufacturing process and a prerequisite for printers to remain successful.

Peter Kiddell, former director of the FESPA UK Association, says Printing 4.0 is “crucial” to the ongoing development of print

“By using the strength of the digital cloud and digital infrastructures to link all elements, we will achieve cost savings and quality improvements along with faster response times across all elements of the system,” he says.

“Adoption of this concept will allow the effective increase in automation, and the adoption of artificial intelligence within certain functions.”

Professional colour management systems will be essential in keeping up with automation and globalised production streams. The use of predictable PDF/X workflow, bespoke ICC device profiles and colorimetric quality control will enable accurate printing that will be required to ensure common-appearance matching across automated printing using a wide variety of inkjet and analogue processes.

Artificial intelligence and printing are going to be bedfellows, Professor Cochrane agrees. “Web-to-print is now mainstream, with AI compiling the majority of the financial reports in the financial industry. This trend can only accelerate into every other field of human endeavour.”

Permanent revolution

R&D engineers and scientists are realising programmable materials using plastic and biological alternatives that can self-repair, change-colour, store energy and offer programmable shape on demand

There is no end to the revolution in sight, Professor Cochrane predicts: “R&D engineers and scientists are realising programmable materials using plastic and biological alternatives that can self-repair, change colour, store energy and offer programmable shape on demand. Unprecedented strength-to-weight ratios and performance with minimal processing cost and maximal material recovery are also emerging.”

While components currently traverse the globe many times from producer to assembly shops, and then on to the final system integrator, if we were to move to material printing and programming close to, or on, the site of use, “we would only have to ship materials in solid, powder and/or fluid form with massive logistic cost reductions,” says Professor Cochrane.

The time to take action is now, advises Peter Kiddell, but not before getting to grips with your current processes to see where to begin updating your approach to business.

“A key to success is to review existing processes and optimise them. There is no point adopting Industry 4.0 if the core activities are not correct.”

Some Industry 4.0 systems are already available to PSPs. Cimpress, the mass customisation provider, uses application programming interfaces (APIs) to offer a spectrum of print services on its Cimpress Open platform. Wide format printers, for example, who want to expand into promotional items such as mugs or umbrellas, can register with the platform and embed services in their own storefronts.

Graeme Richardson-Locke, Technical Support Manager at FESPA, says: “What you get from this is incremental value for processing those extra products that you want to do, but don't want to buy for in-house.”

But there’s a problem: “The more people sign up to Cimpress Open, the less providers there are. It ends up building the Cimpress network, rather than a network of independent printers.”

“Cimpress are very well placed in terms of global fulfilment and to provide a platform. So, if you are a designer with nice ideas, this gives you an instant return fulfilling print without having all the trouble of setting up your print network.

This allows for combining with developers to create links from systems such as EFI Digital StoreFront or Shopify, through to sales, management information and production systems, and buying in a complete print fulfilment platform.

Graeme says: “You can buy solutions like EFI Digital Storefront and get in the game in a meaningful way for around £10,000, but this is not where the money is spent: that goes on populating, setting up, running and marketing that service.”

Seeking advice

“Look very carefully at your current processes,” Peter says. “Are they efficient and effective? Determine what processes already provide digital outputs that indicated their activity and performance. See what level of connectivity there is between processes and equipment.

PSPs should inform themselves about how markets are changing and whether they have the capabilities to manage that change, while accepting they cannot predict everything.

“Expect the unexpected, investigate other applications for their resources and talk to your national FESPA association about how they may benefit from Industry 4.0, and discover who they need to speak to,” says Peter.

Looking to the future, Professor Cochrane sees Industry 4.0 constructing a brave new world: “Add to all this vertical farms in cities and towns growing food at the point of need and the dispersement of energy generation and storage, and we are far closer to real, rather than politically correct, sustainability. And how comfortably it all sits with the internet, IoT, blockchain, the gig economy, publishing, e-commerce and social networks.”

Peter says: “The printing industry has a long and proud history of innovation and change, but at no time has it faced a greater challenge than it does in embracing, and profiting from, the seismic advances in the manufacturing process.”

“If you aren’t able to interconnect with your supply chain and customers then you could be left behind.”

The future of print

The message is clear: in order to survive and thrive in Industry 4.0, PSPs have to carefully weigh up before adopting new technologies. By doing so, they can expect to benefit from enhanced production that will in turn improve the quality of output and the overall service to the customer. Industry 4.0 is an essential step on the path to sustainability. Improving productivity, reducing costs, embedding innovation and de-risking the use of technology are key: the price of standing still is too dear.

FESPA UK is hosting a special event dedicated to Printing 4.0 and how print companies of all sizes can benefit from this approach to business. The Future of Print Conference i4.0 takes place on October 10 at the Manufacturing Technology Centre in Coventry, England.

“The Future of Print Conference will address the challenges, and proposes strategies to respond positively. We aim to show you that no matter the size of the company, everyone can benefit from the techniques,” says Peter.

.png)

The FESPA UK Association invites industry members to its Future Of Print Conference i4.0 on October 10 in Coventry

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Recent news

No minimum order: the growth of DTF decoration

Andy Rogers at Stahls’ UK and Europe, garment decoration firm based in Braintree, UK and Dillingen, Germany, on the cost and speed benefits of direct to film (DTF) printing.

The design democracy: AI, creativity and interior décor

We spoke to Matt Fletcher of John Mark Ltd and Cheryl O’Meara from the Print Pattern Archive about combining age-old techniques with artificial intelligence (AI) to create exciting new motifs for luxury wall coverings.