Restart your engines: Adobe’s new Print Engine version 6

We speak to Mark Lewiecki, Product Manager for Adobe’s PDF Print Engine, about how the newly released version 6 will help to make wide format printing more reliable.

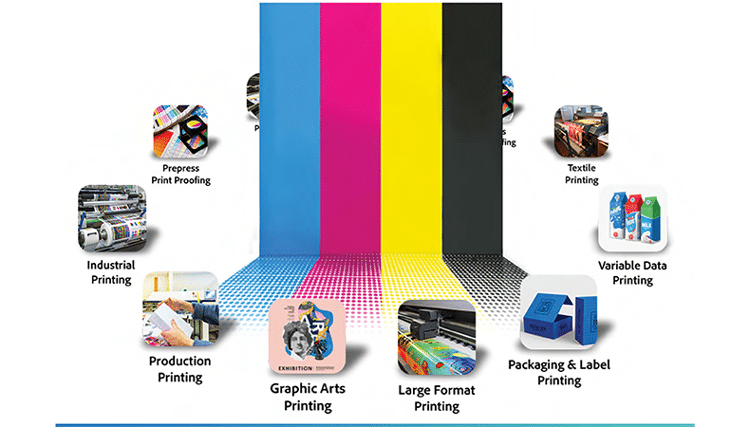

Adobe recently released version 6 of its PDF Print Engine (PE), which features significant new colour processing controls that Adobe says will “enhance every class of inkjet printing” and “deliver the benefits of global standards, developed over many years by industry experts, to commercial printers, publishers and manufacturers”. We spoke to PDF PE Product Manager Mark Lewiecki about how version 6 achieves this.

What are the key benefits of Adobe PDF PE 6 for wide format printers and especially textile printers?

For all wide format printers we’ve added some capability for integrated manufacturing. By that I mean combining manufacturing information – such as cutter paths, or white underprint, or metallic print, or varnishes – with the graphics themselves. For example, a die line is part of many workflows, but it is not tightly connected to the graphics or the PDF file which opens up the opportunity for errors. With PDF PE 6, we put all of that manufacturing data into a PDF file, providing what we call a “single source of truth”.

This offers additional support for PDF Processing Steps and it offers more robust support for spot colours. Spot colours have been used forever as proxies for manufacturing elements, but that’s not what they were designed for in the authoring applications such as the Adobe Creative Cloud (CC) tools, so we’ve made using spot colours more robust for post-press manufacturing.

Consistency plus predictability equals reliability, and that is the name of the game, especially as things are getting more automated and print runs are getting shorter

With regard to textiles, the typical workflow is a block that is repeated – you see that a lot in fabrics. Typically, the core file of that pattern was a TIFF file, an image file format, but now PDF PE 6 enables the use of PDF files for that type of workflow. That opens up a whole range of advantages, since PDF is a much more robust file format than an image format like TIFF.

It’s amazing what you can do with the humble PDF.

Yes, I think sometimes we take it for granted. I occasionally have the opportunity to speak with graphic arts students and I look out at a sea of 20-year-old faces and I realise that they were born after PDF was invented. For them, it’s just always been there. I can remember PDF v1 and how revolutionary it was. For Adobe it started out as an idea and now it’s a billion-dollar business.

And by the way, when one of our founders, John Warnock, first proposed the concept of PDF, he had a real uphill battle to make it happen. There was a lot of scepticism that it would be a success. Today, we take PDF for granted, but its potential remains to be fulfilled, especially in segments like textiles which don’t yet take full advantage of it.

So, what are the most valuable features of PDF PE 6 for wide format printers?

In terms of the benefits of the PDF imaging model and using it at the RIP, you can take advantage of a wider colour gamut and you can emulate the colourways that are used in textiles in different ways.

In terms of integrated manufacturing, if there are cutting marks – and this applies to both textile and also non-textile jobs – the cutting marks can be passed through to the finishing equipment. If you have a knife or laser cutter in your workflow, the outline goes with the file. And if the job gets scaled or rotated, the outline is scaled or rotated with it. That is all seamlessly baked into PDF PE 6 as part of integrated manufacturing.

How does PDF PE 6 integrate with Creative Cloud Applications?

The PDF PE uses, as input, a PDF file, and PDF files are created by CC applications. PDF is an international standard so there’s no secret sauce or special locked-in features here. However, PDF PE 6 is built using the same core PDF technology that is used inside Illustrator, Photoshop and InDesign – I’m talking about things like type rendering, colour management, and so on – it’s the same technology.

What that means is, if you use the same technology to design the job in CC, to then manage the job in Acrobat, and to then render and print the job with PDF PE 6, you get greater consistency, which means more predictability. That means the proof will look more like the on-screen display preview, and it will all look more like what finally gets printed. Consistency plus predictability equals reliability, and that is the name of the game, especially as things are getting more automated and print runs are getting shorter. Using the same core technology across every stage of the workflow results in greater reliability.

PDF PE 6 deals with spectral data and extended gamut printing, but this is not currently supported by CC platforms. Could you tell us about that?

With respect to extended colour gamut printing, what we’re talking about is presses that contain not just the familiar CMYK inks but presses that have additional inks such as orange, green and/or violet, which can enable a larger gamut with less ink. This has been around for quite a long time but it’s finally getting some traction now and, in my opinion, that is due to the result of digital presses.

Typically, in the past, if you wanted to print a spot colour, you had to go to your ink vendor with a swatch and ask them to try to match it. That approach is not available in wide format digital inkjet presses. With digital presses, the press vendors sell the ink – it’s the razor and the razor blade business model – so there are no spot colour inks in wide format, or if there are, they are very expensive and they’re not very feasible. Instead, you have to emulate those spot colours using the available extended colour gamut inks.

We see PDF Print Engine as the first step on the road to complete end-to-end spectral colour workflow

When it comes to support for extended colour gamut in CC, there’s nothing that you need to do differently in the authoring tools such as Illustrator or Photoshop. There’s nothing that we need to add to CC, it’s more about the function of the capabilities of the printing press. However, there is a lot to do in the RIP. PE 6 allows you to have an RGB graphic or image, or a CMYK graphic or image, and then if you go to a press that has more colours, you can take advantage of them.

In terms of spectral data, that is typically captured in a CxF file. When you define a spectral file, the spectral colour also has what can be called an alternate colour, so you give it RGB or CMYK values, or something else, to represent it for display on screen. The CxF file itself can be part of the workflow but right now, the availability to work with spectral values inside of the CC application is not there yet.

There are third-party tools that can embed spectral data into PDF files, tools from Callas software and ColorAnt, or the spectral data files can simply be made available to the RIP. So you take the CxF file, it goes along with the job and you give it to the prepress operator, then the RIP uses it in colour management. That is what PDF PE does in version 6.

There is obviously a need for cloud-based workflows and a number of our partners are already building cloud infrastructures

It’s not an uncommon scenario to have specialty data available to the RIP for RIP-time processing. We hope spectral data will become part of PDF and CC applications in the future, but it’s not a requirement today. Let’s put it this way: there’s no point putting it in CC applications unless a RIP can handle it. Therefore, we’re putting it in the RIP first, which opens the door for spectral colours in authoring applications in the future. We see PDF PE as the first step on the road to complete end-to-end spectral colour workflow.

How long will it be before printers need to think about replacing the PDF PE used in their RIPs?

The PDF PE is built into products by prepress solution providers. In other words, individual printers can’t purchase and install the PDF PE directly; it’s a technology that is built into the software that drives printers.

If a FESPA member has wide format devices powered by RIPs from HP, Caldera, Onyx Graphics, ColorGATE, or EFI Fiery XF, I would say you’ll probably see some announcements about the roll out of PDF PE 6 towards the end of this year. Then, throughout next year you’ll see more announcements about products built on PDF PE 6. It really is dependent on those partners, but I would say printers will probably need to think about it next year, when they will start to be given the option to upgrade from their prepress solution provider.

What is next in the pipeline?

I don’t want to talk about what’s coming from Adobe because we only announce developments when they are ready. But more broadly, there is obviously a need for cloud-based workflows and a number of our partners are already building cloud infrastructures. I think that ripping is probably going to be one of the last things that makes it up into the cloud because of the high bandwidth requirements and also because the quality of service is not always predictable.

Click here find out more about Adobe PDF Print Engine 6.

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Topics

Recent news

New sustainable materials at Sustainability Spotlight

Sustainability Spotlight returned by popular demand to FESPA Global Print Expo last month in an exhibit curated by The Good Factory.

Sportswear Pro: building ‘Brand Me’

After the success of the inaugural Sportswear Pro last month, we spoke with panellist and personalisation expert James Lawrence-Jones about the most exciting revelations at the event.